franklin2

Gold Member

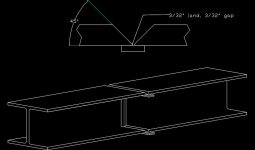

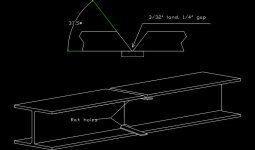

I want to know is the below method the proper way to weld the patch to the I-beam splice? I have a book that says to never weld all the way around the patch, only weld two sides and those sides need to be parallel to the length side of the beam. The book says welding all the way around creates too much stress in the patch and it will tend to crack later. Unless you have a way to heat the whole area red to relax it. I see he welded it at a angle, and I have heard of "fishplating" before. If that is the proper method, how does putting the patch at a angle get rid of the stress from welding all the way around the patch? Just trying to learn something here, not being critical.