Well, I was going to wait and do a full story on my cab so there wouldn't be too many un-answered questions. That way it wouldn't string it out. However, I'll throw it out here and do the best I can. I sometimes don't check in for several days at a time so I may be slow to respond to speciffics.

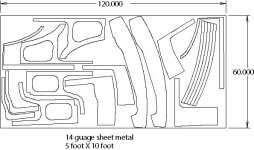

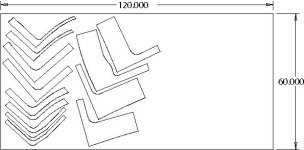

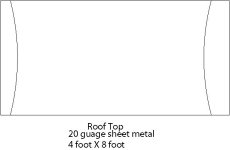

I have spent many hours on the CAD drawing this up - CNC routing out cardboard templates - test fitting and adjusting till I got it where I wanted it. (I have access to CNC router and my brother has CNC plasma cutter) Now I'm ready for sheet metal. This requires 2 sheets of 14 guage 5 foot by 10 foot and 1 sheet 20 guage 4 foot by 10 foot. 1 sheet 3/16" thick scratch resistant plexiglas OR Lexan. I used Lexan MR-10 but plex would be fine.

I will post JPGs of the nested sheets, which I think most of you should be able to open and see. Sorry if you can't. I will also post DXF files of these drawings for anyone that would like to take them to some one in your area that has a CNC plasma OR lazer machine.

Everyone is quite welcome to use/copy/change/ or reproduce these drawings however you wish. I am not interested in protecting them in any way. Just hope they might help out if someone is trying to build there own.

I looked at many different cab designs and probably used some comparisons of a few to get what I liked.

This is intended to be a year-round cab with heat and A/C. Those are still in the works. Also, I still don't have all the corners buttoned up. I will use foam rubber to fill in the space against the engine area as well as the rear corners above the fenders.

I will try to attach a Word file to give more details to anyone interested. That will keep things shorter here.

Cost?

So far:

Sheet metal $194.00 (Brother's COST)

Hinges $18.50

Rubber seals and trim $222.10 McMaster-Carr

and McMaster-Carr

Latches and handles $150.74 Allegis Corporation

and Allegis Corporation

Paint and puddy $102.97

Windows $266.00 (I routed these at work myself)

Wife also includes the misc like Stargon gas, grinding disks etc. but I don't cuz we gotta have that stuff anyhow---Right???

All of these cost will vary depending on your sources and CNC machine time. My CNC work was all free.

Hope the attachments and photos work out here.

I have spent many hours on the CAD drawing this up - CNC routing out cardboard templates - test fitting and adjusting till I got it where I wanted it. (I have access to CNC router and my brother has CNC plasma cutter) Now I'm ready for sheet metal. This requires 2 sheets of 14 guage 5 foot by 10 foot and 1 sheet 20 guage 4 foot by 10 foot. 1 sheet 3/16" thick scratch resistant plexiglas OR Lexan. I used Lexan MR-10 but plex would be fine.

I will post JPGs of the nested sheets, which I think most of you should be able to open and see. Sorry if you can't. I will also post DXF files of these drawings for anyone that would like to take them to some one in your area that has a CNC plasma OR lazer machine.

Everyone is quite welcome to use/copy/change/ or reproduce these drawings however you wish. I am not interested in protecting them in any way. Just hope they might help out if someone is trying to build there own.

I looked at many different cab designs and probably used some comparisons of a few to get what I liked.

This is intended to be a year-round cab with heat and A/C. Those are still in the works. Also, I still don't have all the corners buttoned up. I will use foam rubber to fill in the space against the engine area as well as the rear corners above the fenders.

I will try to attach a Word file to give more details to anyone interested. That will keep things shorter here.

Cost?

So far:

Sheet metal $194.00 (Brother's COST)

Hinges $18.50

Rubber seals and trim $222.10 McMaster-Carr

and McMaster-Carr

Latches and handles $150.74 Allegis Corporation

and Allegis Corporation

Paint and puddy $102.97

Windows $266.00 (I routed these at work myself)

Wife also includes the misc like Stargon gas, grinding disks etc. but I don't cuz we gotta have that stuff anyhow---Right???

All of these cost will vary depending on your sources and CNC machine time. My CNC work was all free.

Hope the attachments and photos work out here.

Attachments

-

NEST 1.jpg42.2 KB · Views: 331

NEST 1.jpg42.2 KB · Views: 331 -

NEST 2.jpg30.1 KB · Views: 236

NEST 2.jpg30.1 KB · Views: 236 -

Roof.jpg15.7 KB · Views: 229

Roof.jpg15.7 KB · Views: 229 -

JD6.JPG392 KB · Views: 373

JD6.JPG392 KB · Views: 373 -

JD5.JPG392.3 KB · Views: 456

JD5.JPG392.3 KB · Views: 456 -

JD1.JPG423.2 KB · Views: 276

JD1.JPG423.2 KB · Views: 276 -

Parts.jpg279.3 KB · Views: 295

Parts.jpg279.3 KB · Views: 295 -

JD7.JPG392.2 KB · Views: 347

JD7.JPG392.2 KB · Views: 347 -

JD8.JPG411.7 KB · Views: 324

JD8.JPG411.7 KB · Views: 324 -

JD9.JPG402.6 KB · Views: 486

JD9.JPG402.6 KB · Views: 486 -

JD10.JPG403.3 KB · Views: 439

JD10.JPG403.3 KB · Views: 439