Teikas Dad

Gold Member

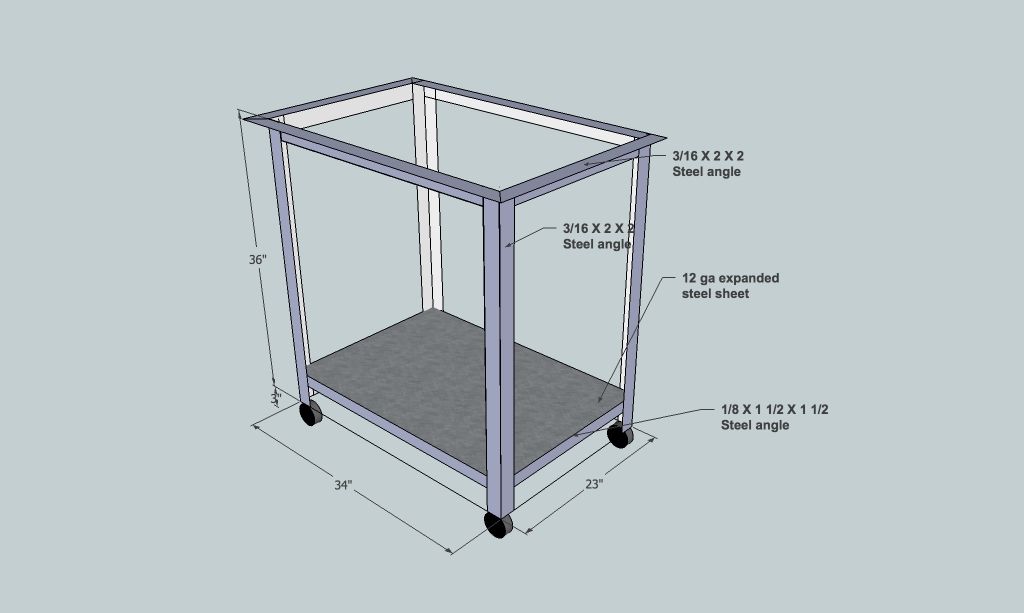

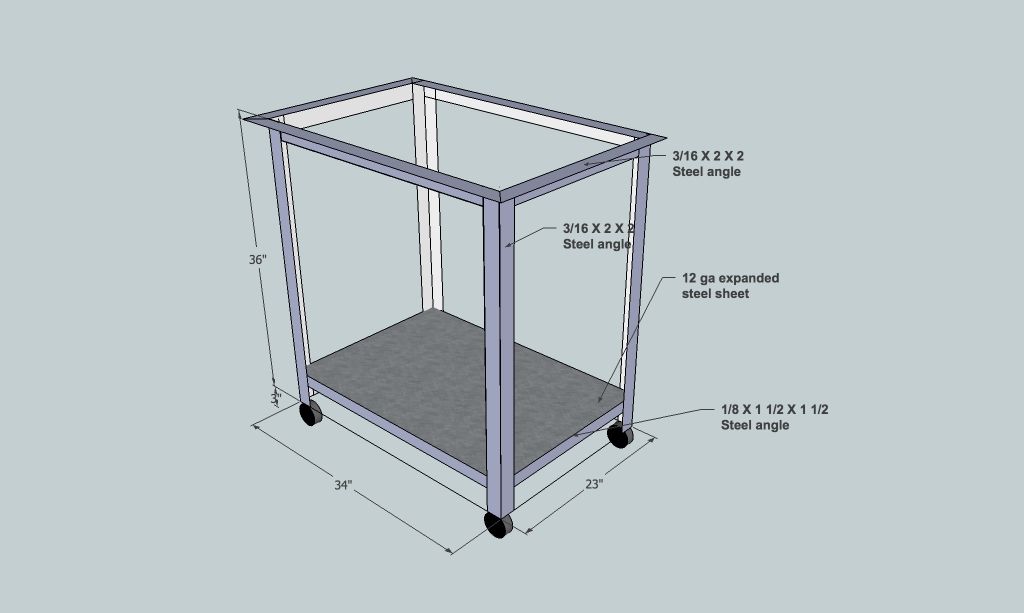

I've read through a bunch of posts here about welding tables looking for ideas.

I'm looking to build a portable table for welding small projects and repairs, not a fabrication table and I came up with a couple different designs. Figured you guys all have a lot more experience welding than I do so I'd post my ideas and see what kind of suggestions, advice or comments I could gather to fine tune my final plan.

Overall size will be 24" X 36" with wheels so I can move it around. I've got limited space in my garage so I can't go too big. I also figured with wheels I can move the table to the open garage door in warm weather for extra ventilation.

I left off the top on both plans so the frame would be easier to see. I' m thinking making the top 40" X 28" that way I'll have a 2" overhang on each end and on the front side for clamps to grab on to. I'll add hangers for clamps, nozzle holder and other items. I may attach a 2" tube on one front corner leg to use for an interchangeable vice/grinder mount.

I'm getting better with Sketch Up so the second plan is a bit better than the first one.

Plan #1 (probably the cheaper version) 2X2X3/16 angle steel frame - 3/8" steel plate top. Top angle steel frame would have the leg facing outboard.

Plan #2 (probably more expensive) 2X2X1/8 square tube frame - 3/8" steel plate top.

I'm looking to build a portable table for welding small projects and repairs, not a fabrication table and I came up with a couple different designs. Figured you guys all have a lot more experience welding than I do so I'd post my ideas and see what kind of suggestions, advice or comments I could gather to fine tune my final plan.

Overall size will be 24" X 36" with wheels so I can move it around. I've got limited space in my garage so I can't go too big. I also figured with wheels I can move the table to the open garage door in warm weather for extra ventilation.

I left off the top on both plans so the frame would be easier to see. I' m thinking making the top 40" X 28" that way I'll have a 2" overhang on each end and on the front side for clamps to grab on to. I'll add hangers for clamps, nozzle holder and other items. I may attach a 2" tube on one front corner leg to use for an interchangeable vice/grinder mount.

I'm getting better with Sketch Up so the second plan is a bit better than the first one.

Plan #1 (probably the cheaper version) 2X2X3/16 angle steel frame - 3/8" steel plate top. Top angle steel frame would have the leg facing outboard.

Plan #2 (probably more expensive) 2X2X1/8 square tube frame - 3/8" steel plate top.