I did a search and didn't find information on this, so forgive me if this has been covered in other posts. I have an old B7100 with a RC60-72H mid-mount mower (It is an RC60 for sure by the label but the rest of the label is missing, I identified it as the RC60-72H by comparing parts diagrams).

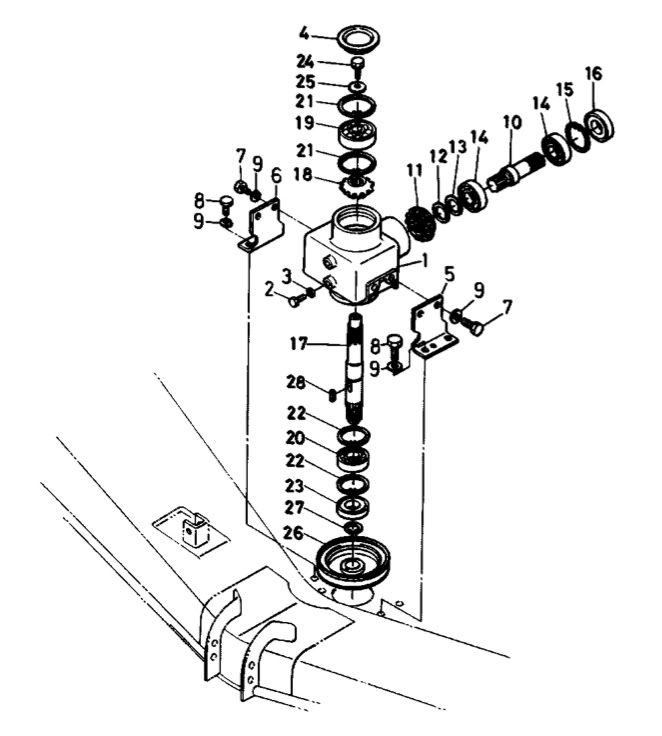

Last time I mowed it seemed to vibrate more than usual and today when I mowed I saw lubricant thrown about the deck. Parked it and saw fluid dripping from the input shaft of the mower. Ran it and watched, and there seemed to be more wobble in the shaft than expected. Turned it off and verified side play in the shaft (maybe 1/8", didn't measure it). My guess is that I need to replace the bearing and seal on the input shaft.

I've done a lot of basic repairs on various machines from lawnmowers to outboard motors, and I have a lot of tools. Is this a reasonable job for the owner or does it need to be done by the dealer? I see Messick's stocks the bearing.

Thanks for any advice and assistance!

Last time I mowed it seemed to vibrate more than usual and today when I mowed I saw lubricant thrown about the deck. Parked it and saw fluid dripping from the input shaft of the mower. Ran it and watched, and there seemed to be more wobble in the shaft than expected. Turned it off and verified side play in the shaft (maybe 1/8", didn't measure it). My guess is that I need to replace the bearing and seal on the input shaft.

I've done a lot of basic repairs on various machines from lawnmowers to outboard motors, and I have a lot of tools. Is this a reasonable job for the owner or does it need to be done by the dealer? I see Messick's stocks the bearing.

Thanks for any advice and assistance!