paulinkansas

Member

The bucket on my 57 hp tractor is 60" wide. It's just a basic bucket with a flat blade. I plan on moving/digging alot of earth, rocks, roots, limbs and other hard materials with it for the next few years.

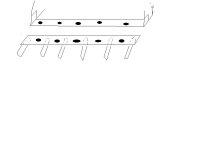

I've looked at many toothbars, but want to build my own. Every toothbar I've seen bolts onto the 2 sides of a bucket (one bolt on each side), and they also have a lip or something like that on each tooth that hooks around the existing cutting edge of the bucket.

I was thinking about making a toothbar that would bolt on directly to the bottom of the bucket instead of the sides. The toothbar would still have a lip that would overlap the existing cutting edge, and the bolts would have a "backing plate" on the other side of the bucket that it's mounted to.

Does anyone think of anything wrong with this idea? I thought that the existing bucket might be a little weaker with the mounting holes that would have to be drilled into it, but I really doubt that I would be removing the toothbar once it's bolted on.

I've looked at many toothbars, but want to build my own. Every toothbar I've seen bolts onto the 2 sides of a bucket (one bolt on each side), and they also have a lip or something like that on each tooth that hooks around the existing cutting edge of the bucket.

I was thinking about making a toothbar that would bolt on directly to the bottom of the bucket instead of the sides. The toothbar would still have a lip that would overlap the existing cutting edge, and the bolts would have a "backing plate" on the other side of the bucket that it's mounted to.

Does anyone think of anything wrong with this idea? I thought that the existing bucket might be a little weaker with the mounting holes that would have to be drilled into it, but I really doubt that I would be removing the toothbar once it's bolted on.