jorswift

Silver Member

- Joined

- Jan 2, 2018

- Messages

- 110

- Location

- Upland, IN

- Tractor

- JD955, MF1528, JD2240, JD 4300, Ford Jubilee

Hello all,

I am new to the forum and somewhat to the tractor world. I have a Ford Jubilee for a couple of years that I am trying to sell. But I picked up a used 4300 with loader, scaper blade and box blade with trailer for a reasonable price (I believe).

I have never owned a diesel machine. I have never had a tractor with 4x4, loader, etc. Anything I need to watch out for? Any mods or anything to do to the tractor to help it out or me?!

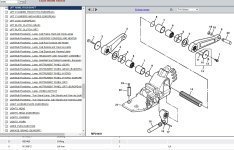

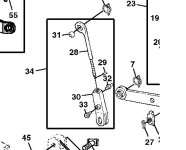

I used it for the first time this weekend, temps were -5* F, to cut and move some wood. I have a carryall with pallet box on. Well after loading the carryall with some wood, the left lift control arm snapped. Is this something they are prone to do? I didn't even have that much weight. The tractor lifted it pretty easy.

Thanks in advance for all the much needed advice and help!

I am new to the forum and somewhat to the tractor world. I have a Ford Jubilee for a couple of years that I am trying to sell. But I picked up a used 4300 with loader, scaper blade and box blade with trailer for a reasonable price (I believe).

I have never owned a diesel machine. I have never had a tractor with 4x4, loader, etc. Anything I need to watch out for? Any mods or anything to do to the tractor to help it out or me?!

I used it for the first time this weekend, temps were -5* F, to cut and move some wood. I have a carryall with pallet box on. Well after loading the carryall with some wood, the left lift control arm snapped. Is this something they are prone to do? I didn't even have that much weight. The tractor lifted it pretty easy.

Thanks in advance for all the much needed advice and help!