Ty in MN

New member

- Joined

- Jul 10, 2021

- Messages

- 2

- Location

- Minnesota

- Tractor

- IH 140, Ford 4000, Sperry-New Holland L425

Hello All,

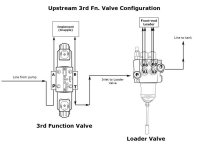

I have a Sperry-New Holland L425 that we have completely rebuilt, repowered engine, complete sandblast and paint, etc. We finally got everything back together and have been fighting for days to get the power beyond/auxiliary hydraulics to work. My father had a third valve on it in the past but he cant remember how he plumbed it. I bought an auxiliary hydraulic kit from Summit Hydraulics that is designed for open center systems and has two momentary buttons to open and close a cylinder, in this case a backhoe (front hoe?) and a grapple bucket. Both home made of course. We've run into two problems. 1) Zero pressure from the power beyond port on the control valve. We put a 0-5000 psi gauge inline and got a big fat zero. There is oil present so it's getting in there but it's not doing us much good. 2) Per the instructions we installed the new valve straight from the pump with the exit going back to the control valve. This moved the cylinder but because it was too long it bent the rod like a banana. That's not actually the problem however. The real problem is that it killed the engine at low rpm when the rod was fully closed. At high RPM it blew an O-ring right out of one of the lines. Our theory is the oil has no where to go when the cylinder is either fully extended or retracted and it dead heads. For the life of me I cannot understand how they can market the kit as being capable of being installed before the control valve if there is no where for the oil to go. My assumption is I am completely missing something important here. Any thoughts?

Thanks!

I have a Sperry-New Holland L425 that we have completely rebuilt, repowered engine, complete sandblast and paint, etc. We finally got everything back together and have been fighting for days to get the power beyond/auxiliary hydraulics to work. My father had a third valve on it in the past but he cant remember how he plumbed it. I bought an auxiliary hydraulic kit from Summit Hydraulics that is designed for open center systems and has two momentary buttons to open and close a cylinder, in this case a backhoe (front hoe?) and a grapple bucket. Both home made of course. We've run into two problems. 1) Zero pressure from the power beyond port on the control valve. We put a 0-5000 psi gauge inline and got a big fat zero. There is oil present so it's getting in there but it's not doing us much good. 2) Per the instructions we installed the new valve straight from the pump with the exit going back to the control valve. This moved the cylinder but because it was too long it bent the rod like a banana. That's not actually the problem however. The real problem is that it killed the engine at low rpm when the rod was fully closed. At high RPM it blew an O-ring right out of one of the lines. Our theory is the oil has no where to go when the cylinder is either fully extended or retracted and it dead heads. For the life of me I cannot understand how they can market the kit as being capable of being installed before the control valve if there is no where for the oil to go. My assumption is I am completely missing something important here. Any thoughts?

Thanks!