Hi guys!

Just bought myself my very first tractor about a month ago. My dad used to have one, and I've been wanting one for a couple of years for clearing snow and stuff. I'm a service advisor in a multi-brand car workshop and used to be a technician so I figured I'd try to find a cheap faulty one. Came over a MT180HD that had been sitting for a year with a faulty tranny. Read just about all the threads on here about these little fighters and figured I could give it a go.

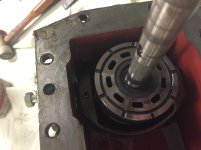

Got her on my trailer and back to the shop, fearing that it was the HST charge pump that needed replacement. I took off the low pressure relief vale and fired her up and let the pump fill a bottle. Both pressure and flow looked good. I then check the LP and HP relief valves and the natural valve and all seemed fine. It was apparent that the tractor had been split before, and from what I could see the last mech were anything but meticulous. I suspected that this might have something to do with it, and since I had power on the charge pump and PTO I knew I had power into the tranny. I also knew I had oil flow to the HST pump, but it didn't seem to get further. Also, there was absolutely no hydraulic sound when I moved the pedal. I took off the pedal assy and found that the axel going in to the swash plate was loose, meaning that the sping pins must have broken off.

I split the tractor and found that they only put one pin in, holding only one side of the shaft to the swash plate. This had to take up all the force and vibrations, resulting in high wear on the other end. This led to the bore in the swash plate getting bigger resulting in additional force on the one spring pin that eventually broke.

I measured the axel and this was fine, only a bit of marks on it but not measurable wear. The softer swash plate had taken the beating and the hole was at least 1,2 mm off in one end. Since buying a new plate would cost me several 100 $ and probably take a while I used a reamer (I thing this is the English name) with to get the hole centred again and took it up a couple of mm. My friend has a lathe in his workshop so we made a bushing to fit the hole and then reamed the hole to fit the axel. I put it all together again after also changing the shot clutch release bearing and fired her up last night. All is working well and so far no leaks

Next it to refit the cab, change the oil in the front diff and then re-change the oil in the engine and tranny after running it a little while. The old oil looked like it had been there a while..

Have enjoyed reading the other posts here, and hope this post can help someone sometime

Just bought myself my very first tractor about a month ago. My dad used to have one, and I've been wanting one for a couple of years for clearing snow and stuff. I'm a service advisor in a multi-brand car workshop and used to be a technician so I figured I'd try to find a cheap faulty one. Came over a MT180HD that had been sitting for a year with a faulty tranny. Read just about all the threads on here about these little fighters and figured I could give it a go.

Got her on my trailer and back to the shop, fearing that it was the HST charge pump that needed replacement. I took off the low pressure relief vale and fired her up and let the pump fill a bottle. Both pressure and flow looked good. I then check the LP and HP relief valves and the natural valve and all seemed fine. It was apparent that the tractor had been split before, and from what I could see the last mech were anything but meticulous. I suspected that this might have something to do with it, and since I had power on the charge pump and PTO I knew I had power into the tranny. I also knew I had oil flow to the HST pump, but it didn't seem to get further. Also, there was absolutely no hydraulic sound when I moved the pedal. I took off the pedal assy and found that the axel going in to the swash plate was loose, meaning that the sping pins must have broken off.

I split the tractor and found that they only put one pin in, holding only one side of the shaft to the swash plate. This had to take up all the force and vibrations, resulting in high wear on the other end. This led to the bore in the swash plate getting bigger resulting in additional force on the one spring pin that eventually broke.

I measured the axel and this was fine, only a bit of marks on it but not measurable wear. The softer swash plate had taken the beating and the hole was at least 1,2 mm off in one end. Since buying a new plate would cost me several 100 $ and probably take a while I used a reamer (I thing this is the English name) with to get the hole centred again and took it up a couple of mm. My friend has a lathe in his workshop so we made a bushing to fit the hole and then reamed the hole to fit the axel. I put it all together again after also changing the shot clutch release bearing and fired her up last night. All is working well and so far no leaks

Next it to refit the cab, change the oil in the front diff and then re-change the oil in the engine and tranny after running it a little while. The old oil looked like it had been there a while..

Have enjoyed reading the other posts here, and hope this post can help someone sometime

Last edited: