JazzDad

Gold Member

I am trying to use the B-I-L's 1966 diesel Ford 3000. It worked fine last November.

Today it started right up, but moving the throttle makes no change in the engine speed. With the throttle pulled wide open, the engine runs at about 700 RPM (a guess, broken tach). If I move the throttle to idle, the engines slowly winds down until it dies. There is a hole (normally plugged) in the piping between the air filter and the intake manifold, probably drilled to allow ether injections. I pulled the plug to restart the engine, and it started after a long time of cranking. I went to plug the hole and checked the suction I was expecting to feel - air was blowing out of it. ( ? )

As said, it will start with a long crank time. If I put a load on it (mowing deck) it has only enough power to creep along in 2nd gear, and bogs down if it encounters just slightly thicker grass.

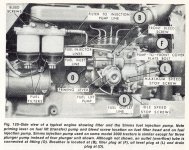

The throttle linkage seem to be all connected, and I can see a little half-moon shaped arm on the opposite side of the pump (?) where there are adjustable stops for idle and full throttle. The linkage travel is from stop to stop.

Exhaust cap opens straight up on start up, and I see no blockage in the air intake piping or filter.

Fuel was treated in November with Enzyme brand stabilizer (as it has been for some time).

Any thoughts?

Today it started right up, but moving the throttle makes no change in the engine speed. With the throttle pulled wide open, the engine runs at about 700 RPM (a guess, broken tach). If I move the throttle to idle, the engines slowly winds down until it dies. There is a hole (normally plugged) in the piping between the air filter and the intake manifold, probably drilled to allow ether injections. I pulled the plug to restart the engine, and it started after a long time of cranking. I went to plug the hole and checked the suction I was expecting to feel - air was blowing out of it. ( ? )

As said, it will start with a long crank time. If I put a load on it (mowing deck) it has only enough power to creep along in 2nd gear, and bogs down if it encounters just slightly thicker grass.

The throttle linkage seem to be all connected, and I can see a little half-moon shaped arm on the opposite side of the pump (?) where there are adjustable stops for idle and full throttle. The linkage travel is from stop to stop.

Exhaust cap opens straight up on start up, and I see no blockage in the air intake piping or filter.

Fuel was treated in November with Enzyme brand stabilizer (as it has been for some time).

Any thoughts?

Last edited: