I over tightened one the cap screws (D) when changing the transmission fluid. I removed the

Suction screen cleaned and reinstalled. I have since lost the cap screw, it must have vibrated off. Is there an inexpensive repair that I can tackle my self or is this a dealer issue? Any help will be appreciated.

MX12150, MX12314

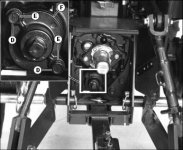

5. After oil is drained, remove two cap screws (D), two lock washers (E) and suction screen cover (F).

Suction screen cleaned and reinstalled. I have since lost the cap screw, it must have vibrated off. Is there an inexpensive repair that I can tackle my self or is this a dealer issue? Any help will be appreciated.

MX12150, MX12314

5. After oil is drained, remove two cap screws (D), two lock washers (E) and suction screen cover (F).