You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

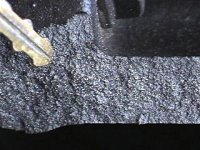

Picture of broke rockshaft 4300, Saplings!?

- Thread starter erisque

- Start date

- Views: 3541

/ Picture of broke rockshaft 4300, Saplings!?

#1

Jag

Gold Member

- Joined

- Apr 6, 2000

- Messages

- 443

- Location

- Central Arkansas

- Tractor

- Kubota /L2650/ LA450/B4690 -- John Deere 450 Dozer

Man, bad picture, how did you do that.............

I pretty much covered it in earlier posts, but I was boxblading, clearing a small lot of palmettos and shrubs. I backed up and was attempting to get the box blade over a mound of sand, dirt etc. Not successful, I pulled forward to reposition from a different angle, then it just literally exploded. I'm not sure if the damage was caused by backwards force or when I pulled forward. I do know that I was not Hound doggin the machine, and this piece should really "not break". I am beginning to believe the 6" box blade the dealer sold me is to much for this machine. It can pull or push it full, but may be to heavy for the castings and internal components. They probably are good machines, but I purchased this one for Brushhogging and light land clearing, the dealer knew this and said it could do it. Well, I guess that depends on how many times they want to repair it. I average less than 1 job per repair. Just for the hell of it, I jumped over to Kubota owning to see what types of problems those machines encounter. Am I missing something? I could not find any real problems listed under Kubotas, maybe a leaking tire or general problems that come with owning any machine. On a few older kubotas I see a few hydraulic problems and maybe a few other more serious issues, which is to be expected with older, larger machines, But I must say, and IT HURTS, I actually love my JD, But the Kubota site doesn't even come close to matching the number of serious issues listed on The JD site?? Any one have an explanation???

Attachments

DDT

Platinum Member

- Joined

- Dec 18, 2000

- Messages

- 953

- Location

- Clay Center, Kansas

- Tractor

- Kubota M6040/cab, BX25D, RTVX900

erisque

I have a 4300 as well. I use a 1700LB rear concrete weight on the 3 point when I do heavy work. Like removeing small trees up to 8" dia. also use grass seeders (primary & overseeder) I do ALOT of dirt work, small basements and crawl spaces for house additions that are too small for a CAT. I don't under stand how your tractor broke like that. I'm assumeing that A range and very low ground speed is used for tuff projects. I don't understand.

DDT

I have a 4300 as well. I use a 1700LB rear concrete weight on the 3 point when I do heavy work. Like removeing small trees up to 8" dia. also use grass seeders (primary & overseeder) I do ALOT of dirt work, small basements and crawl spaces for house additions that are too small for a CAT. I don't under stand how your tractor broke like that. I'm assumeing that A range and very low ground speed is used for tuff projects. I don't understand.

DDT

CVHoss

Gold Member

erisque,

I've got a 4400 that, I believe, is pretty much a twin to the 4300 except for engine hp. Your profile doesn't list much info so I don't know how many hours you have on the tractor. I only have 49 on mine, but they're all "working" hours. Have done some brush/sapling cutting for a friend of mine, dug out the pond for the wife's horses, done some clearing on my land project, tilled up over 22,000 sq. feet of hard, dry pasture that hadn't been turned in 30 yrs., and haven't had any breakage yet. I did have a problem with the front loader not lining up correctly after I took it off and reinstalled it the first time, but the dealer replaced half of the loader assembly with no problem. In everything I've done, there's always been something hanging off the 3-point. While pushing out a tree stump, I even managed to do this to a drag link:

I'm thinking that what has happened to you isn't indicative of any product problem with the entire line, but rather that you just happened to get a "lemon" tractor. And, from the sounds of your other posts, it doesn't appear that you've got the greatest dealer to work with. While he may be covering these things under warranty, it sounds like his mechanics may be less than qualified.

Hoss

I've got a 4400 that, I believe, is pretty much a twin to the 4300 except for engine hp. Your profile doesn't list much info so I don't know how many hours you have on the tractor. I only have 49 on mine, but they're all "working" hours. Have done some brush/sapling cutting for a friend of mine, dug out the pond for the wife's horses, done some clearing on my land project, tilled up over 22,000 sq. feet of hard, dry pasture that hadn't been turned in 30 yrs., and haven't had any breakage yet. I did have a problem with the front loader not lining up correctly after I took it off and reinstalled it the first time, but the dealer replaced half of the loader assembly with no problem. In everything I've done, there's always been something hanging off the 3-point. While pushing out a tree stump, I even managed to do this to a drag link:

I'm thinking that what has happened to you isn't indicative of any product problem with the entire line, but rather that you just happened to get a "lemon" tractor. And, from the sounds of your other posts, it doesn't appear that you've got the greatest dealer to work with. While he may be covering these things under warranty, it sounds like his mechanics may be less than qualified.

Hoss

Erisque,

I have a Kubota L3410 HST and no problems outside of leaky hydro filters at -35F. The Deere 4300 as my first choice, but the dealer and to some extent, the issue with the first generation front axle pushed me to the Kubota. (Orange also gave a lower price with more stuff)

From what I have heard, the might be slightly more "issues" with the Deere 4000 series than with the Kubota "L" series. But not so many as to be an indictment against Deere! You must have gotten a bum machine. Have you contacted the Deere corporate headquarters? It may be time to play "squeaky wheel".

Best of Luck!

John Bud

I have a Kubota L3410 HST and no problems outside of leaky hydro filters at -35F. The Deere 4300 as my first choice, but the dealer and to some extent, the issue with the first generation front axle pushed me to the Kubota. (Orange also gave a lower price with more stuff)

From what I have heard, the might be slightly more "issues" with the Deere 4000 series than with the Kubota "L" series. But not so many as to be an indictment against Deere! You must have gotten a bum machine. Have you contacted the Deere corporate headquarters? It may be time to play "squeaky wheel".

Best of Luck!

John Bud

cowboydoc

Super Member

- Joined

- Dec 23, 2000

- Messages

- 6,725

- Tractor

- JD 8320 MFWD, JD 6415 MFWD, FEL, and cab, John Deere MFWD 4600, John Deere 4020, John Deere 4430, John Deere 455 mower, Deutz, and Gehl 4610 perkins skidsteer

I think the problem is not the machine but you bound up the linkage there. I have had the same thing happen on big tractors if you bind them up. One time I put the posthole pounder arm too short and it broke off just like yours on a JD 4440. Now there's no shortage of metal on one of those.

iamgott

Bronze Member

Hi cowboy, well, actually, I think there is a slight flaw in this piece to. On the rockshaft housing, there is a casting seam right down the middle, then you have the oil fill hole right in the middle also, which in turn, is very close to the top hole on the upper link attaching point. I realize they probably have done extensive testing on all the components. But testing doesn't always reveal all weak spots on all components in all conditions. circumstances.

If you get a chance, look at yours real close, to myself, haveing the oil fill right in the casting seam, and just above the attachment point for the upper link, has got to weaken it.

Mine split right down the middle, right down the seam, and "THEN" it snapped off on the sides. I also was using the top hole at the time, as it was easier to insert the pin without having to raise or lower the control arms. "they block the lower holes in certain positions".

A friend who worked as General Manager for a John Deere Dealer said the feedback sensor was adjusted to tight and caused the internal components to bind against the case. I myself, Ive never seen the insides "how their made or move". I do know that they have had this adjustment off several times, when I would raise the box, when it got to the top of its travel, the valve would not disengage, and actually put a stall on the engine/pump. If I lowered it, the engine rpm would come up and run normal. I took it to be fixed just a few weeks ago. They called and said it was done. As I was Loading it on the trailer, it started doin it again. I had to argue and demonstrate to the dealer to prove it. Finally, the mechanic came out and adjusted a rod sticking out the back, and it was fixed!! Now I wonder what they charged john deere for fixin somethin else that wasn't even broke?

If you get a chance, look at yours real close, to myself, haveing the oil fill right in the casting seam, and just above the attachment point for the upper link, has got to weaken it.

Mine split right down the middle, right down the seam, and "THEN" it snapped off on the sides. I also was using the top hole at the time, as it was easier to insert the pin without having to raise or lower the control arms. "they block the lower holes in certain positions".

A friend who worked as General Manager for a John Deere Dealer said the feedback sensor was adjusted to tight and caused the internal components to bind against the case. I myself, Ive never seen the insides "how their made or move". I do know that they have had this adjustment off several times, when I would raise the box, when it got to the top of its travel, the valve would not disengage, and actually put a stall on the engine/pump. If I lowered it, the engine rpm would come up and run normal. I took it to be fixed just a few weeks ago. They called and said it was done. As I was Loading it on the trailer, it started doin it again. I had to argue and demonstrate to the dealer to prove it. Finally, the mechanic came out and adjusted a rod sticking out the back, and it was fixed!! Now I wonder what they charged john deere for fixin somethin else that wasn't even broke?