TX mower

Bronze Member

Facing replacement of some hoses and a leaking control valve for my YFL-1500 loader, I'm considering adding a Rear Aux valve while I'm at it. Still over twice as old as my tractor, a hydraulic top link and maybe some other things would be appreciated by these aging bones  . I do lots of box-blade work and the box has drop-down ripper-teeth on front of the blade (manually operated) which could be converted to hydraulic operation adding huge convenience. I'm also considering the purchase of a flail mower, maybe with side-shift.

. I do lots of box-blade work and the box has drop-down ripper-teeth on front of the blade (manually operated) which could be converted to hydraulic operation adding huge convenience. I'm also considering the purchase of a flail mower, maybe with side-shift.

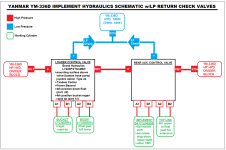

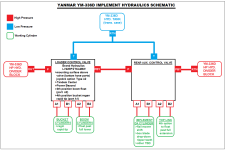

The 336D has a built-in Divider Block for implement hydraulics and is a constant flow hydraulic system so open ("Tandem") center is required for all control valves and each must have Power Beyond and a Low Pressure return to the tank (fitting on side of transmission case). I'd appreciate folks' review of the attached schematics and correction / comment to help me get this right the first time.

A particular question about the LP return to tank and the reason for two schematics ..... Is a check valve required on each LP return lines to prevent 'backfeed' of LP oil between the two valves? There is only one port for the tank on the tractor so I must use a "T" fitting to join the two LP returns before the return port on the transmission case. The existing loader LP return has no check valve, I've no concern about backfeed from the vented tank - just not sure if some limited backfeed may occur at the "T" from one valve to another or if that's a concern at all?

I'm still trying to figure out the best 2-spool valve to use for the rear aux control, so suggestions most welcome, both type and brand/model number. Valves for a top mounting plate with bottom ports will allow my best installation options. I've read lots of discussion here on pros/cons of having float on at least one rear aux spool ... I know I won't use it with my box-blade, much preferring the YM336D's fantastic draft control; but I can see that it might be useful with things like my shredder where I could eliminate the noisy and limited-travel 'float strap' at it's upper-link connection. I'd rather spend a few more bucks now and get all the options I might ever need.

One rear-valve notion I've had is simply using a 2-spool FEL valve with 4th position float on port A2 and 4th position regen on port A1. Maybe not traditional to have a joystick as opposed to two-levers for rear aux but I can install it 'forward facing' beside me with a convenient joystick location for my right hand and the use of the 4th positions would be optional. I can source such an FEL valve for very little more $ than many two-spool valves and the monoblock is very compact which is attractive.

Anyway, feedback and suggestions from this experienced crowd most welcome on any of this. Thanks In Advance!

The 336D has a built-in Divider Block for implement hydraulics and is a constant flow hydraulic system so open ("Tandem") center is required for all control valves and each must have Power Beyond and a Low Pressure return to the tank (fitting on side of transmission case). I'd appreciate folks' review of the attached schematics and correction / comment to help me get this right the first time.

A particular question about the LP return to tank and the reason for two schematics ..... Is a check valve required on each LP return lines to prevent 'backfeed' of LP oil between the two valves? There is only one port for the tank on the tractor so I must use a "T" fitting to join the two LP returns before the return port on the transmission case. The existing loader LP return has no check valve, I've no concern about backfeed from the vented tank - just not sure if some limited backfeed may occur at the "T" from one valve to another or if that's a concern at all?

I'm still trying to figure out the best 2-spool valve to use for the rear aux control, so suggestions most welcome, both type and brand/model number. Valves for a top mounting plate with bottom ports will allow my best installation options. I've read lots of discussion here on pros/cons of having float on at least one rear aux spool ... I know I won't use it with my box-blade, much preferring the YM336D's fantastic draft control; but I can see that it might be useful with things like my shredder where I could eliminate the noisy and limited-travel 'float strap' at it's upper-link connection. I'd rather spend a few more bucks now and get all the options I might ever need.

One rear-valve notion I've had is simply using a 2-spool FEL valve with 4th position float on port A2 and 4th position regen on port A1. Maybe not traditional to have a joystick as opposed to two-levers for rear aux but I can install it 'forward facing' beside me with a convenient joystick location for my right hand and the use of the 4th positions would be optional. I can source such an FEL valve for very little more $ than many two-spool valves and the monoblock is very compact which is attractive.

Anyway, feedback and suggestions from this experienced crowd most welcome on any of this. Thanks In Advance!

Attachments

Last edited: