srjones

Platinum Member

- Joined

- Mar 6, 2006

- Messages

- 542

- Location

- Columbia County, Oregon, USA

- Tractor

- Mahindra 2015HST & Mitsubish R1500

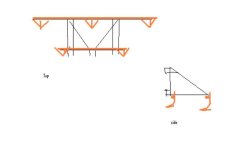

I got these parts today, as they were going to be scrapped and I just couldn't let that happen.

From reading the various posts about "cultivators" I've noticed that there as many different types of cultivators as there are spoken languages in Europe. Given that, I probably don't have the right name for this thing (or what this thing was) but I would describe it as a "spring shank feild cultivator"

So I ask you, fair and wise TBNer's, please educate me on what this is and perhaps make some suggestions to help me turn it into a much smaller configuration.

My questions:

1. Does anyone have a link or picture of what this thing might have looked in its pre-scrap condition?

2. I counted 7 shanks and I know that's waaaay to much for my 20 horse CUT. Any recommendations of how many I might reasonably expect to pull? And spacing between?

3. Should put them in a straight formation or a V formation?

4. There are two 'sod cutter disk wheel thingys' (no, I don't know what they're called) Where do they go? I can see how they'd be perfect for slicing through sod, but maybe it has a completly different purpose.

5. What are the advantages and limitations of using springs like this?

6. Since I might be able to make two (or three) separate cultivators out of this are any suggestions of special purpose cultivators I might consider? Right now, I'm thinking of a standard garden/crop cultivator and also a specialized tool for cutting and dressing shallow ditches.

Thanks in advance,

-Steve

From reading the various posts about "cultivators" I've noticed that there as many different types of cultivators as there are spoken languages in Europe. Given that, I probably don't have the right name for this thing (or what this thing was) but I would describe it as a "spring shank feild cultivator"

So I ask you, fair and wise TBNer's, please educate me on what this is and perhaps make some suggestions to help me turn it into a much smaller configuration.

My questions:

1. Does anyone have a link or picture of what this thing might have looked in its pre-scrap condition?

2. I counted 7 shanks and I know that's waaaay to much for my 20 horse CUT. Any recommendations of how many I might reasonably expect to pull? And spacing between?

3. Should put them in a straight formation or a V formation?

4. There are two 'sod cutter disk wheel thingys' (no, I don't know what they're called) Where do they go? I can see how they'd be perfect for slicing through sod, but maybe it has a completly different purpose.

5. What are the advantages and limitations of using springs like this?

6. Since I might be able to make two (or three) separate cultivators out of this are any suggestions of special purpose cultivators I might consider? Right now, I'm thinking of a standard garden/crop cultivator and also a specialized tool for cutting and dressing shallow ditches.

Thanks in advance,

-Steve