strantor

Platinum Member

I've been looking for a decent 250+A MIG machine for a couple of years now. I have a 200A TIG that suits all my needs but it's a pain in the behind to always have to TIG things what don't need TIG'in. MIG is much faster and easier to get set up and and also weld. I got spoiled at my last job where we had a small fab area with a Millermatic 252. Been looking to buy something comparable ever since I left there. I check Craigslist and Facebook marketplace daily or weekly depending on how much money have in the pocket, waiting on a good deal. Actually what I've been looking for is a broken MIG machine that I can fix. I gots some electrical and electronical smarts. I don't know how the used welder market is across the country, but in my area people seem to think welders depreciate no more than 1% per year. People are trying to sell 10 y/o buzzboxes for $10-$20 less than brand new ones in the store. I thought for sure I'd be able to find a broken machine for scrap price. No such luck. Then two weeks ago I happened upon this listing:

Based on my familiarity with this market I considered this deal "too good to be true." I barely looked at it. Coming back to the marketplace and seeing them still listed for sale day by day eventually built up my curiosity. I figured they were probably flooded in Harvey but regardless I did a little research on them and found that (according anonymous & uncited sources on other forums) they were from the early 1990's and weren't very popular in their day. They were ahead of their time. Synergic welders with a panel chock full of buttons and electronic boards. I get the impression they weren't marketed to the right demographic. They were full-featured welders that belonged in commercial shops, being marketed to weekend warriors who were used to having two knobs. They didn't sell well, and production was stopped after just a short time. Spare parts are hard to find, and expensive. So maybe that's why they're so cheap. They're busted and the parts to fix them don't exist. Interesting.... So I went to look at them.

One of them looked pretty rough and the seller didn't seem to know much about them. He said one works but doesn't maintain constant wire speed and the other one doesn't work at all. He didn't know which was which. That was the description he received from the guy he got them from years ago, and he never plugged them in. He wasn't sure if the spoolgun worked. He didn't have anywhere to plug them in for me to verify tbey even powered on, but I decided to take a chance since I didn't see any flood damage and buy them in hopes that with the parts from two complete welders I could at least get one working one, and maybe sell any remaining working spares for at least the $500 I bought them for.

I let them sit for a few days until yesterday I decided to tackle one of them. I chose the one without the spoolgun. The one with the crusty white face and red primer splashed all over it. I chose that one because it had no spool in it, so I assumed it was the one that didn't work at all. I figured it probably had a simpler problem, like a blown fuse or 'sploded capacitors. Powered it up, it came on, but wouldn't weld. Found corrosion where the gun plugs in, on both sides of the from fascia. Cleaned that up and it worked just fine. I tested it with Argo from my TIG and it sucked as expected but it didn't seem to have any speed issues. So I think I "fixed" the one that "didn't work at all."

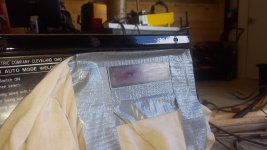

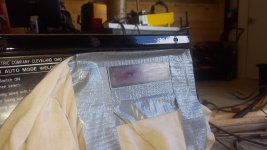

Since it apparently works just fine, I decided to make it pretty. Chipped off all 26 years worth of dribbled epoxy and splashed paint, peeling finish and petrified stickers, and gave it new coat of paint. The front fascia was white and crusty with paint overspray or peeling finish, not sure, but it scraped off easily with a credit card and a pocket knife. The protective layer over the LCD was petrified, yellow, and cracked. It was barely readable. I very carefully scraped/chipped it away and painted over it with my wife's clear fingernail polish. It's much better now.

The MIG gun itself after being cleaned, seems brand new. Probably worth as much as the welders.

So one down, one to go. I hope to get both of these functional and have one setup for mild steel and one setup for stainless & aluminum. I will update the thread with pictures from the 2nd machine when I get around to fixing it up.

Based on my familiarity with this market I considered this deal "too good to be true." I barely looked at it. Coming back to the marketplace and seeing them still listed for sale day by day eventually built up my curiosity. I figured they were probably flooded in Harvey but regardless I did a little research on them and found that (according anonymous & uncited sources on other forums) they were from the early 1990's and weren't very popular in their day. They were ahead of their time. Synergic welders with a panel chock full of buttons and electronic boards. I get the impression they weren't marketed to the right demographic. They were full-featured welders that belonged in commercial shops, being marketed to weekend warriors who were used to having two knobs. They didn't sell well, and production was stopped after just a short time. Spare parts are hard to find, and expensive. So maybe that's why they're so cheap. They're busted and the parts to fix them don't exist. Interesting.... So I went to look at them.

One of them looked pretty rough and the seller didn't seem to know much about them. He said one works but doesn't maintain constant wire speed and the other one doesn't work at all. He didn't know which was which. That was the description he received from the guy he got them from years ago, and he never plugged them in. He wasn't sure if the spoolgun worked. He didn't have anywhere to plug them in for me to verify tbey even powered on, but I decided to take a chance since I didn't see any flood damage and buy them in hopes that with the parts from two complete welders I could at least get one working one, and maybe sell any remaining working spares for at least the $500 I bought them for.

I let them sit for a few days until yesterday I decided to tackle one of them. I chose the one without the spoolgun. The one with the crusty white face and red primer splashed all over it. I chose that one because it had no spool in it, so I assumed it was the one that didn't work at all. I figured it probably had a simpler problem, like a blown fuse or 'sploded capacitors. Powered it up, it came on, but wouldn't weld. Found corrosion where the gun plugs in, on both sides of the from fascia. Cleaned that up and it worked just fine. I tested it with Argo from my TIG and it sucked as expected but it didn't seem to have any speed issues. So I think I "fixed" the one that "didn't work at all."

Since it apparently works just fine, I decided to make it pretty. Chipped off all 26 years worth of dribbled epoxy and splashed paint, peeling finish and petrified stickers, and gave it new coat of paint. The front fascia was white and crusty with paint overspray or peeling finish, not sure, but it scraped off easily with a credit card and a pocket knife. The protective layer over the LCD was petrified, yellow, and cracked. It was barely readable. I very carefully scraped/chipped it away and painted over it with my wife's clear fingernail polish. It's much better now.

The MIG gun itself after being cleaned, seems brand new. Probably worth as much as the welders.

So one down, one to go. I hope to get both of these functional and have one setup for mild steel and one setup for stainless & aluminum. I will update the thread with pictures from the 2nd machine when I get around to fixing it up.