Pineridge,

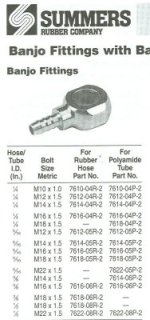

re: "Are you sure that the banjo fittings that they have available can't be modified for your needs?"

Thanks a lot for the offer!

Actually I called this morning and the guy I talked to said they didn't have ANY banjos in stock. In fact he didn't even recognize the part numbers at first and questioned where I was getting the part numbers from (I was looking at the same listing you posted). He finally did find a couple of the numbers in the computer but said they didn't have any in stock, didn't have any costs loaded for them, and had no idea how long it would take to get some. I was hoping to get someone to take some measurements off of the hose barb shoulder so I could insure there was enough room to bore it out for 1/2" tubing. He said he would have to call me back and took my number. That was first thing in the morning west coast time, and I haven't heard anything yet. I think he said their supplier was overseas, I'll just bet they come from India.

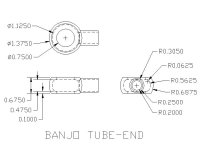

I was considering getting an 18mm banjo and boring it out 1mm and then taking a die grinder and opening up the banjo bore slightly and maybe porting the hole just a bit to improve the flow capacity.

Or, I could use a 22mm banjo... If you took a 19mm copper crush-washer (19mm ID, 27mm OD) and centered it over the 22mm banjo hole, then take something like a large square or diamond shaped object and used it to peen three or four spots into the 22mm hole slightly, those peened-over spots would keep the 19mm ID washer centered over the 22mm ID hole and the ID of the washer would keep the 19mm banjo bolt centered. Then when you tighten the hollow bolt it would form a shoulder in the copper washers that would keep the bolt centered nicely in the banjo. There would be plenty of shoulder to make a good reliable connection, especially if you keep everything reasonably well centered this way. The 22mm banjo would certainly allow for plenty of flow.

Whether 18mm or 22mm (whichever had been available), I still had to make sure the hose barb shoulder had enough OD to be drilled out to 1/2" ID.

All of which seems to be academic if they've got to order them in small quantity custom for my order, it starts sounding expensive.

I am pretty well resigned to fabricating them on the lathe. Oh well, I enjoy lathe work. Just takes time. It will be fun to post some pics. /forums/images/graemlins/smirk.gif