DuckHunterJon

Bronze Member

- Joined

- Apr 18, 2004

- Messages

- 50

Ok, so my first caveat is this isn't 100% related to my tractor, but I'm going to use tractor parts to build, so I'm hoping I can ask this here. I'm building a long tail mud motor for my duck boat and I was hoping to get some advice on seals. The arrangement is basically a 6.5 hp Honda motor, coupled to a U Joint, coupled to a 3/4" x 60" driveshaft, coupled directly to a prop.

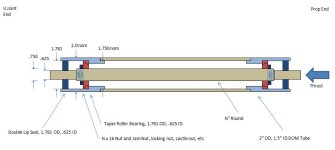

The driveshaft will sit in a 2" DOM housing, suspended by tapered roller bearings on either end (to take thrust load of the prop). Outboard of the bearings, I plan on using double lip seals to seal out water, in grease/oil/atf (haven't decided on lubricant yet). My question - is there any hope of the seal lasting as the prop will be run 1:1 off the motor (3200 RPM's). I've contemplated having the OD of the shaft ground to improve surface finish, but it of course will add cost. This is really only important at the prop end, as it will reside in the water - but I will also have a seal at the motor/ujoint end to keep lubricant in the bearings.

Second question, any reccomendations on U-Joints? The angle will be 12 - 14 degrees from the driveshaft to the motor, and again, WOT is 3200 rpm's (possibly a bit more if everything works well, and I can turn down the governor a bit). I know I need to go with a needle bearing unit, but beyond that - can a standard PTO shaft UJoint from TSC hold up to that RPM and loading?

Any other info/advice on this project will be welcome. I have all the tools to cut, weld, form, etc - the only thing I plan on farming out will be the turning. On the odd chance there is anyone on here with a lathe in the Western NY area that would be interested in helping out, I'd be happy to hear from them.

Thanks.

The driveshaft will sit in a 2" DOM housing, suspended by tapered roller bearings on either end (to take thrust load of the prop). Outboard of the bearings, I plan on using double lip seals to seal out water, in grease/oil/atf (haven't decided on lubricant yet). My question - is there any hope of the seal lasting as the prop will be run 1:1 off the motor (3200 RPM's). I've contemplated having the OD of the shaft ground to improve surface finish, but it of course will add cost. This is really only important at the prop end, as it will reside in the water - but I will also have a seal at the motor/ujoint end to keep lubricant in the bearings.

Second question, any reccomendations on U-Joints? The angle will be 12 - 14 degrees from the driveshaft to the motor, and again, WOT is 3200 rpm's (possibly a bit more if everything works well, and I can turn down the governor a bit). I know I need to go with a needle bearing unit, but beyond that - can a standard PTO shaft UJoint from TSC hold up to that RPM and loading?

Any other info/advice on this project will be welcome. I have all the tools to cut, weld, form, etc - the only thing I plan on farming out will be the turning. On the odd chance there is anyone on here with a lathe in the Western NY area that would be interested in helping out, I'd be happy to hear from them.

Thanks.