YardBikeBob

Silver Member

What is the prevailing wisdom (oxymoron?) on sharpening the blades on a rotary cutter? Yes, there is a pretty good 2-year old thread on this.

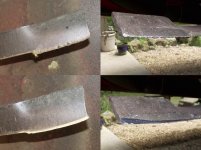

It was time to mow again and I noticed the tips of growing grass looked more bludgeoned than cut previously. Time to look at the blade.

It looked awful. So I dragged out the 4 1/2 angle grinder and went after it. I left the blades on the cutter and just worked them over from the back of the implement. A half hour of effort including finding an extension cord. I was amused that the 'spec' is a 1/16th edge -- like me and my grinder could hold to that.

It did mow a lot better. The grass was a foot high and the tractor went through it like a hot knife through butter. Unfortunately, humans are creatures of habit and/or stupid and I started at the periphery of the field and worked inward. The edges of the field is where the rocks grow better. So by the time I got to the 'pretty' part of the field, the blades were dinged up again. OTOH, if I could be more careful, that 1/2 hour of effort got demonstrably better results.

Before the sharpening, the blades were so banged up I'm surprised they cut at all. That must be a lesson in what a heavy metal blade with the cutting edge like a chunk of rebar will do at 200mph.

Bob

It was time to mow again and I noticed the tips of growing grass looked more bludgeoned than cut previously. Time to look at the blade.

It looked awful. So I dragged out the 4 1/2 angle grinder and went after it. I left the blades on the cutter and just worked them over from the back of the implement. A half hour of effort including finding an extension cord. I was amused that the 'spec' is a 1/16th edge -- like me and my grinder could hold to that.

It did mow a lot better. The grass was a foot high and the tractor went through it like a hot knife through butter. Unfortunately, humans are creatures of habit and/or stupid and I started at the periphery of the field and worked inward. The edges of the field is where the rocks grow better. So by the time I got to the 'pretty' part of the field, the blades were dinged up again. OTOH, if I could be more careful, that 1/2 hour of effort got demonstrably better results.

Before the sharpening, the blades were so banged up I'm surprised they cut at all. That must be a lesson in what a heavy metal blade with the cutting edge like a chunk of rebar will do at 200mph.

Bob