frogpond

Silver Member

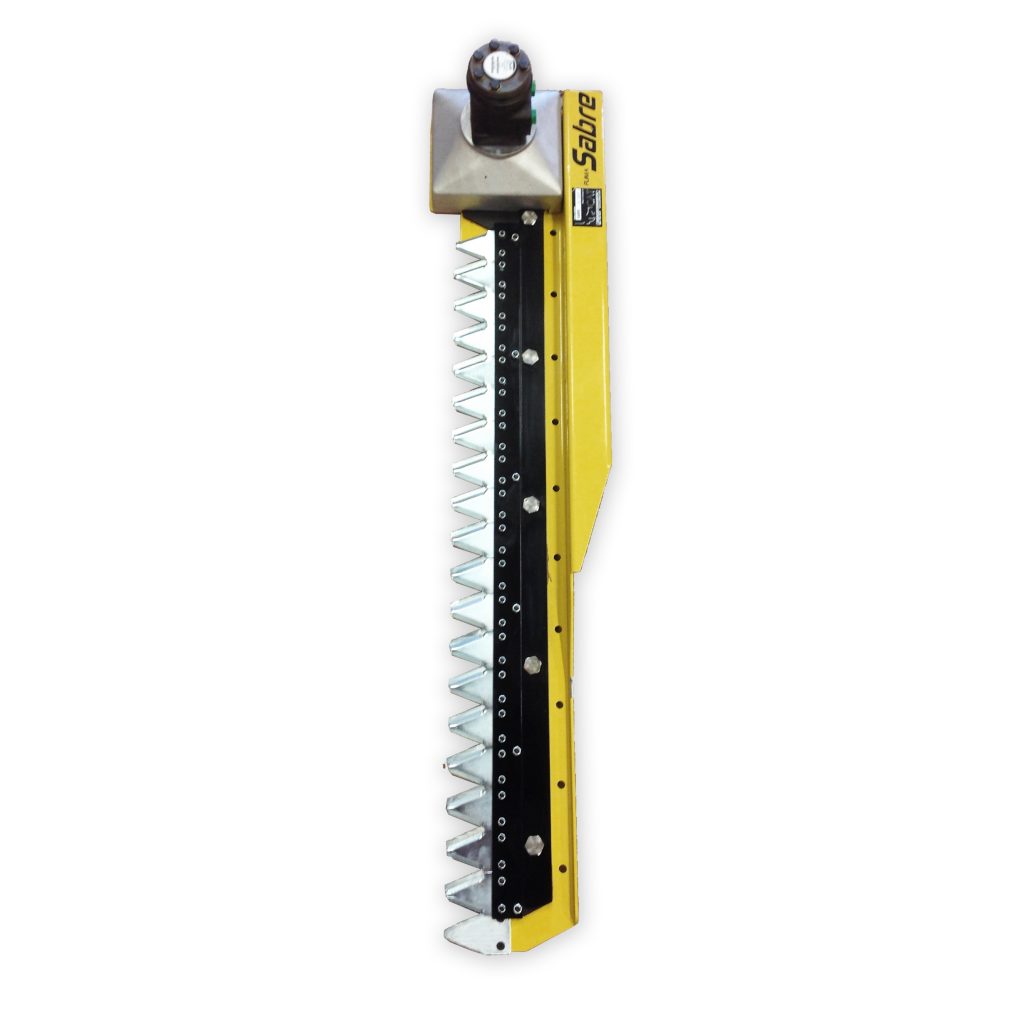

On my bx25d, I have a wimpy Samurai Sabre sickle bar brush cutter. It clamps onto the loader bucket, and is powered by a cam on a hydraulic motor, hooked up to my 3rd function hoses. My hydraulic pressure tests at about 1800 psi or a little less. Will I gain blade speed and/or power if I shim the hydraulics up more, say to 2000 psi? Or is an external pump and tank the only way?