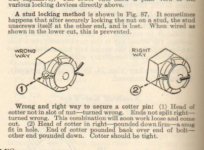

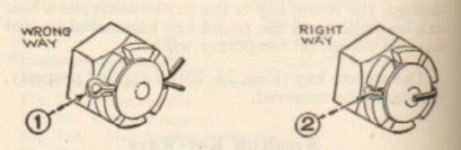

This spring I removed the stump jumper of my 5’ King Kutter rotary mower to replace the seal. I didn’t re-use the cotter pin because it was pretty well mangled, so I used the biggest one I had in my box o parts. I’m pretty sure it was a Harbor Freight special. Anyway, I installed it the “right” way as shown in this diagram I found somewhere on the internet today.

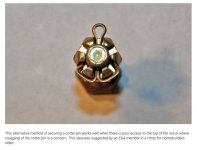

Yesterday afternoon my stump jumper fell off while I was mowing. Luckily it just dropped straight off and didn’t go spiraling thru my skull on the way out. I found myself a new castle nut and washer and bought the largest diameter good quality cotter pin that would fit. Because of the sort of abuse a rotary mower takes it made sense to me that leaving a leg of the cotter pin down past the end of the shaft exposes it to damage, so I installed this one the “wrong” way. It was only after installing it and mowing for an hour that I began second guessing myself and I found this diagram.

Does it make a difference? I contoured the legs around the bolt pretty well with a hammer. I suppose I could install a new one but I’m not certain that some diagram on the Internet is relevant to this particular application.

Yesterday afternoon my stump jumper fell off while I was mowing. Luckily it just dropped straight off and didn’t go spiraling thru my skull on the way out. I found myself a new castle nut and washer and bought the largest diameter good quality cotter pin that would fit. Because of the sort of abuse a rotary mower takes it made sense to me that leaving a leg of the cotter pin down past the end of the shaft exposes it to damage, so I installed this one the “wrong” way. It was only after installing it and mowing for an hour that I began second guessing myself and I found this diagram.

Does it make a difference? I contoured the legs around the bolt pretty well with a hammer. I suppose I could install a new one but I’m not certain that some diagram on the Internet is relevant to this particular application.