wolfpack2

Gold Member

Just got back from the dealer after taking my TC40D in to get the 3PT fixed and the 1200 hr service performed.

The Problem:

The 3PT would hiccup to the point that it was getting dangerous and I was afraid of further damage. The 3PT had also gotten to the point that it would drop down in less than 1 minute after I shut off the tractor. Made it a pain to put jack stands under the mower to scrape the deck or change blades. It would either bounce and knock the stands around or drop before I could get them under the deck.

What the dealer found:

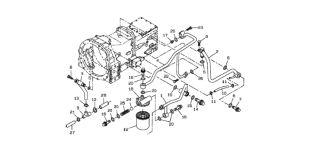

After inspecting the tractor and based on their previous experience, they found that the hose clamps on the "T" fitting of the suction line were loose. This was allowing air into the system and foaming the oil. The foam was preventing the spool vale and cylinder from working properly. They tightened up the fitting, cycled the 2 pt several times, and all is good. The tractor was close to its 1200 hour service, so I had them do that while it is there.

I have read a few threads lately about 3PTs failing and being rebuilt which is what I was expecting as the cure. Had I known it was only a loose clamp, I could have save myself a repair bill (couple hours of shop time to test and diagnose the problem). Still cheaper than a rebuild. Which I would have done if my back was up to it only to find it would not have solved the problem. The funny thing is the hydrostatic transmission acted normal as did the loader. Only the 3PT seemed to be affected. I'm just glad I have an honest dealer and they took the simple route first instead of just tearing into it and rebuilding the cylinder based on the obvious system.

I though I would pass along the information in case someone else finds themselves in a similar situation. Hate to see someone go to the trouble to tear down and rebuild the lift just to find that it didn't solve the problem.

The Problem:

The 3PT would hiccup to the point that it was getting dangerous and I was afraid of further damage. The 3PT had also gotten to the point that it would drop down in less than 1 minute after I shut off the tractor. Made it a pain to put jack stands under the mower to scrape the deck or change blades. It would either bounce and knock the stands around or drop before I could get them under the deck.

What the dealer found:

After inspecting the tractor and based on their previous experience, they found that the hose clamps on the "T" fitting of the suction line were loose. This was allowing air into the system and foaming the oil. The foam was preventing the spool vale and cylinder from working properly. They tightened up the fitting, cycled the 2 pt several times, and all is good. The tractor was close to its 1200 hour service, so I had them do that while it is there.

I have read a few threads lately about 3PTs failing and being rebuilt which is what I was expecting as the cure. Had I known it was only a loose clamp, I could have save myself a repair bill (couple hours of shop time to test and diagnose the problem). Still cheaper than a rebuild. Which I would have done if my back was up to it only to find it would not have solved the problem. The funny thing is the hydrostatic transmission acted normal as did the loader. Only the 3PT seemed to be affected. I'm just glad I have an honest dealer and they took the simple route first instead of just tearing into it and rebuilding the cylinder based on the obvious system.

I though I would pass along the information in case someone else finds themselves in a similar situation. Hate to see someone go to the trouble to tear down and rebuild the lift just to find that it didn't solve the problem.