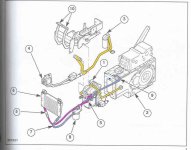

I made a separate post to address your question about foaming, the charge pump pressure, and suction. Below is a piping diagram that shows the flow.

Suction from the main hydraulic pump and the HST charge pump are both applied to the same supply line. If you look just below callout #3 in this diagram, you will see the main hydraulic filter and a pipe going to a flange that attaches to the side of the transmission. The main filter is a suction filter. If it is not tight, you can draw air in around its gasket. As the fluid is drawn up the yellow-colored pipe, it comes to a "Y". That "Y" can easily be seen if you look under your tractor. it is a black plastic assembly with hose clamps holding it in place. This "Y" boot can be a source of suction leaking and air drawn into the line if it is not tight. Check it for leaks, damage, and tightness.

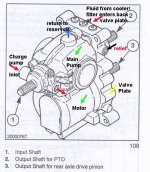

From the "Y" adapter, follow the yellow line up and into the snout of the HST transmission. (There's no need to follow the line going to the main hydraulic pump.) Where the yellow pipe goes into the transmission, there is a charge pump. I have added labels to the 2nd illustration below. You can clearly see where the charge pump is located.

The outlet of the charge pump can be as high as 200+ PSI. It sends fluid out the pink-colored pipe to the HST cooler. Notice that this pink pipe attaches to a fitting on top of the HST filter. That is a ball-check pressure relief valve that will bypass the HST cooler if the fluid is very cold and too much pressure is in the line. Normally all fluid goes to the cooler, but is some instances, this bypass valve may open. When it does, some people hear a clicking sound and think there is something wrong. This is completely normal.

When the fluid leaves the HST cooler (blue pipe) it goes to the HST filter under pressure and then is supplied at low pressure into the main HST pump. The charge pump's function is to draw fluid from the reservoir, send it to the cooler, and supply it to the HST transmission pump in sufficient quantities to keep the main pump from cavitating.

The main pump then varies pressure and flow depending on the swashplate angle. Because your HST pedal pivot plate is broken you cannot vary the swashplate angle.

Also, your Rabbit/Turtle switch peforms a unique function for our transmissions. It is a pressure actuated change in the HST motor swashplate angle. Very few HSTs allow changing of the motor's swasplate like ours does. When you press the Rabbit or Turtle button, you energize a solenoid that opens a valve. Pressure from the charge pump is used to also change the motor swashplate angle. The rabbit position of the solenoid sends 175 psi to the motor's swashplate. The turtle position sends zero psi.

So, by using the diagrams below, you should be able to troubleshoot your piping and find if you have any leaks. My guess is the frothing of the fluid you saw may be normal. You will have some idea when you can better test your internal pressure maximum and see if it is 5000 psi before the relief valves lift.

Good luck with your repair. Believe me, I KNOW just how big a pain this can be.