stagelines

Member

- Joined

- Apr 13, 2010

- Messages

- 33

- Location

- Mountains of Southern California

- Tractor

- Kubota L4330 Grand L

Hello all

Is anyone familiar with the thread used on the transmission oil inlet of the Kubota L4330?

I have a Bush Hog post hole digger model # 2102, with the optional down force kit.

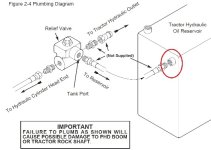

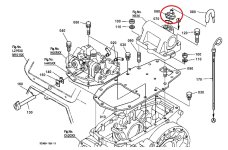

I am trying to plumb the downforce hydraulics to a Kubota L4330 Grand L tractor, but there is no available auxilliary inlet port as shown in the bushhog diagram, so i need to plumb into the existing oil fill.

The stock plug is plastic. I would prefer to use metal for the adapter.

i am unable to identify the threads of the fill port. i spent a few hours researching thread standards, and uncovered more than i ever wanted to know about the subject.

For example- twenty-three different exterior features of the thread ridge- per the Japanese Industrial Thread Specifications

The major diameter of the external thread (fill plug threads O.D.) is 1.272", which converts to 32.3088 mm. The thread count appears very close to 11 TPI (i only have an SAE pitch guage), which converts to 2.3091 mm. The thread is not tapered.

A few other very informative links i ran across.

Identifying Thread | Metric, Tapered, Parallel, and British Threads

THREAD IDENTIFICATION CHART

Japanese Thread Types- for Couplers

Thank you in advance for any help you could throw my way

Michael

Is anyone familiar with the thread used on the transmission oil inlet of the Kubota L4330?

I have a Bush Hog post hole digger model # 2102, with the optional down force kit.

I am trying to plumb the downforce hydraulics to a Kubota L4330 Grand L tractor, but there is no available auxilliary inlet port as shown in the bushhog diagram, so i need to plumb into the existing oil fill.

The stock plug is plastic. I would prefer to use metal for the adapter.

i am unable to identify the threads of the fill port. i spent a few hours researching thread standards, and uncovered more than i ever wanted to know about the subject.

For example- twenty-three different exterior features of the thread ridge- per the Japanese Industrial Thread Specifications

The major diameter of the external thread (fill plug threads O.D.) is 1.272", which converts to 32.3088 mm. The thread count appears very close to 11 TPI (i only have an SAE pitch guage), which converts to 2.3091 mm. The thread is not tapered.

A few other very informative links i ran across.

Identifying Thread | Metric, Tapered, Parallel, and British Threads

THREAD IDENTIFICATION CHART

Japanese Thread Types- for Couplers

Thank you in advance for any help you could throw my way

Michael