Shimon

Platinum Member

Not sure if I should post here or in Lawn & Garden...mods move post if necessary.

Bought an LX178 (94 model) with the 44" mulching deck. I'm cleaning up the deck and sharpening the blades. When I first got the mower deck turned over (three spindles with two blades each for total of 6 blades) I found the two outer sets of blades would spin independently of the pulleys which told me they weren't torqued down all the way. The center set of blades spun together with the pulley.

Now I'm putting it all back together and the manual says to torque everything down to 55 ft-lbs. I'm trying to tighten the bolts but need a way to keep the pulleys from spinning. Is it ok to stick a screwdriver through one of the four openings in the pulley and hold the pulley against the aluminum spindle housing? I just don't want to break anything. Is there a better way to keep the pulleys stationary so I can torque the bolts to 55 ft-lbs?

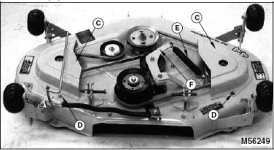

Enclosed is a photo of the top of the deck from the manual. The openings in the pulleys can be seen in the top most pulley (the other two pulleys are under the side covers). The other photo is from the operators manual.

Bought an LX178 (94 model) with the 44" mulching deck. I'm cleaning up the deck and sharpening the blades. When I first got the mower deck turned over (three spindles with two blades each for total of 6 blades) I found the two outer sets of blades would spin independently of the pulleys which told me they weren't torqued down all the way. The center set of blades spun together with the pulley.

Now I'm putting it all back together and the manual says to torque everything down to 55 ft-lbs. I'm trying to tighten the bolts but need a way to keep the pulleys from spinning. Is it ok to stick a screwdriver through one of the four openings in the pulley and hold the pulley against the aluminum spindle housing? I just don't want to break anything. Is there a better way to keep the pulleys stationary so I can torque the bolts to 55 ft-lbs?

Enclosed is a photo of the top of the deck from the manual. The openings in the pulleys can be seen in the top most pulley (the other two pulleys are under the side covers). The other photo is from the operators manual.