I have a Kama TS254C and am having a problem with the 3 point hitch not raising.

With the cover off of the liftbox, and the tractor running, fluid is running out of the valve from the hole just above the inlet tube. This does not change no matter where I put the lift lever.

This hole connects to what is called the "spill valve" in my parts manual.

I took the valve apart, and found nothing obviously wrong. I reassembled the valve, with new o-rings, and the lift worked 2 or 3 times and then stopped working again.

One thing that I noticed when I took the valve apart, was that the smaller "spool" in the spill valve sleave fit very tightly. The machined surface on the outside of this "spool" looked good, I did not see any gouges or burs. The inside of the sleave also seemed smooth.

I don't understand what this "spill valve" really does. nothing connects to the "spool" in question. Does hydraulic pressure make it move?

If anyone has had one of these valves apart please let me know how tight these piece should fit.

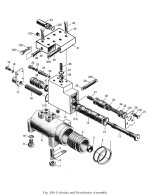

For lack of anything better to try, I was going to replace the sleave and 2 spools in the spill valve. Unfortunately, the valve in my tractor is not exactly the same as the one shown in the parts manual that came with the tractor, so I doubt that the part numbers shown are correct.

I have read postings here that have stated that the lift box in the Kama TS254 is the same as the one used in the 300 series Jinma. Pictures and diagrams that I have seen online for the Jinmas, certainly look like my liftbox.

Can anyone verify that the parts from the 300 series Jinma will fit in the Kama liftbox. I do not want to order parts that will not work.

Stan

With the cover off of the liftbox, and the tractor running, fluid is running out of the valve from the hole just above the inlet tube. This does not change no matter where I put the lift lever.

This hole connects to what is called the "spill valve" in my parts manual.

I took the valve apart, and found nothing obviously wrong. I reassembled the valve, with new o-rings, and the lift worked 2 or 3 times and then stopped working again.

One thing that I noticed when I took the valve apart, was that the smaller "spool" in the spill valve sleave fit very tightly. The machined surface on the outside of this "spool" looked good, I did not see any gouges or burs. The inside of the sleave also seemed smooth.

I don't understand what this "spill valve" really does. nothing connects to the "spool" in question. Does hydraulic pressure make it move?

If anyone has had one of these valves apart please let me know how tight these piece should fit.

For lack of anything better to try, I was going to replace the sleave and 2 spools in the spill valve. Unfortunately, the valve in my tractor is not exactly the same as the one shown in the parts manual that came with the tractor, so I doubt that the part numbers shown are correct.

I have read postings here that have stated that the lift box in the Kama TS254 is the same as the one used in the 300 series Jinma. Pictures and diagrams that I have seen online for the Jinmas, certainly look like my liftbox.

Can anyone verify that the parts from the 300 series Jinma will fit in the Kama liftbox. I do not want to order parts that will not work.

Stan