if there are alot of rocks, i would say backhoe. if a trencher won't work.

2800' is long.

every now and then i will see 4" field culvert hose on a basically a large over sized garden hose reel. but in this case it was a tow behind trailer. that the hose was pulled off from.

i don't know if you could take pallet forks maybe on the front loader of a tractor. and then at the very tip of the pallet forks run some sort of bar between the forks. and pull hose off that way or not.

===========

get the pipe run below frost line for your area. so you don't have to worry about pipes freezing.

========

you will find it that the plastic pipe is going to be curvy and go in all directions. if you leave it set out in the hot sun ((late spring / summer)) the plastic can heat up enough during the day, and cool off during the night. to help remove some of the curvy-ness. and make it easier to put down into a trench.

you have a couple things to deal with. you noted "hilly" and you also wanted to make it easier pressure testing the line initially and down the road for leaks.

=======

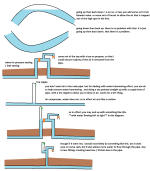

the "hilly" ground. were the pipe goes up then back down (like an upside down U) you will most likely need to provide an "air bleeder valve, or a watering spigot/faucet. in the highest point of the upside down U's in the pipe run to remove trapped air.

the pressure testing thing. about all i could suggest if it was really that important to test the pipe line sections down the road. would be at the end of each 500 feet. would be come up and out of the ground. for both pipe ends. using galvanized pipe and put yourself a valve. along with an air bleeder or water spigot. so you can bleed out air.

=======

if ya have not caught on. air being in the main hose run can be a major problem. air can form in a pipe run just from regular use. or water just setting in the pipe. it does not require you to have a leak. and needing to air bleed air may be one of them things you do every so often to hardly ever. exception on maintenance / repairs.

=======

my other concern is ""water hammering"" think of water hammer like a truck/car/tractor slamming into hill to stop. for water, water slams into 90's and inside of the pipe and fittings. when it does this the force has to go some place. for truck/car/tractor it would mean dents and things being broken. for water it means pipes and fittings getting cracked. for older homes, folks tend to remember the rattling of pipes in the house. ((this would be ""water hammering"" you can buy "water hammering devices" for homes. that are fairly small and help. or you can build your own. though they can be bigger when DIY.

if ya notice shaking of the water spigot when ya shut the valve down. then ya most likely experiencing "water hammering"

==========

my other concern is if you end up using a bunch of water say at the very end of this 2800' say for washing down a tractor. or something odd ball. you may get a lot of water pressure right off the get go. but after say 5 to 15 minutes running the water. your pressure may start to drop off rapidly, along with amount of water you end up getting. and it could come down to a slow trickle.

if ya look at attach picture and the bottom last 2 diagrams. there be a partial reason for going with very bottom diagram. and that is to help reduce headloss / friction loss. so you might have a couple extra minutes of higher pressure and amount of water initially at the end of the 2800 feet. ((i say a couple minutes but that is only a guess, without knowing specifics. ))

specifics would be. how much water GPH (gallons per hour) or GPM (gallons per minute) or how much water usage daily at each water spigot and fittings and distance between everything. and details on pump, and wanted pressure in the pipe run.