1msucub

New member

- Joined

- Feb 10, 2015

- Messages

- 11

- Location

- Hernando, MS

- Tractor

- 1964 Massey Ferguson 165, 2015 Kubota L2501

Before I get started, let me say a couple of things.... First, I absolutely love reading these forums. I believe some of the smartest, most adaptable individuals on earth are farmers. The amount of technical knowledge some of y'all have on here is amazing, so hats off to you. Secondly, I searched back years on this and other forums for the answer to my issue and struck out, so here I am. I am only posting this here and on the hydraulics forum. No other boards, unless someone here directs me otherwise.

I have a 1964 MF 165 that is/was equipped with Multipower. The lever is present, but the linkage is not hooked up. The electrical plug on top of the tranny housing that I read somewhere was also a part of it is present but the wires are cut. After pulling the top plate off, I found that the Multipower pump is also present but the top fitting where the line runs forward to the tranny is not connected (present but no line attached). The pump can be seen in the last two pictures I attached.

This is only relevant because my 3 pt lift is VERY weak, slow, and shaky (previous owner disclosed that when I bought it). I drained the fluid, which had minimal metal shavings, and flushed out the filter, which was in pretty good shape. You should be able to tell that the gears appear in excellent shape. New fluid and clean filter made zero difference in lifting ability. Therefore, I can't imagine it being anything other than the pump.

Everything I read said I'd need to split the tractor in order to remove the pump if the tractor was fitted with Multipower, but I'm just not setup to do that safely. Therefore, I tried it anyway. In order to even have a chance, I had to remove the small MP pump that sits to the front left of the housing, attached to the main hydraulic pump. Since it just pumped fluid up and right back out into the housing, I saw no harm. It got down to a couple of millimeters (not kidding) but I was able to wiggle it out. Made my day.

You should be able to tell in the pictures that the MP pump attaches to the main pump by bolting onto a heavy piece of angled iron that is bolted onto the main pump itself. There are NO line/fluid attachments between the two. The small pump has a gear in the back that is driven by the large gear in the back of the main pump. It is now rendered useless, and I don't intend on reattaching it. Here's the heart of my issue... This is the first time I've ever taken a tractor apart like this (thank goodness for the internet and the simplicity of old, reliable equipment) and I have no idea how to really assess what kind of shape the interior workings of this pump are in. The pump itself looks great (damage/wear-wise), but that, of course, doesn't determine functionality.

Ultimately, here are my questions:

1. Is there any reason why I couldn't leave the old MP pump off?

2. What am I looking for as far as signs of wear in my pump?

3. Where do I draw the line between rebuilding (kits seem to be $175-250) or replacing ($400-900) the pump?

4. How do I determine exactly what pump I'm dealing with (there are 2-3 out there that apparently are slightly different, but those differences seem important)?

5. Who do y'all trust for these type of parts? I've used Stevens in Louisiana, Yesterdays Tractor and a couple others and been pleased...

6. Is there anything more gratifying than doing something like this that you've never done before and impressing your two young sons?

Thanks so much in advance... Now to try to attach these pictures...

I have a 1964 MF 165 that is/was equipped with Multipower. The lever is present, but the linkage is not hooked up. The electrical plug on top of the tranny housing that I read somewhere was also a part of it is present but the wires are cut. After pulling the top plate off, I found that the Multipower pump is also present but the top fitting where the line runs forward to the tranny is not connected (present but no line attached). The pump can be seen in the last two pictures I attached.

This is only relevant because my 3 pt lift is VERY weak, slow, and shaky (previous owner disclosed that when I bought it). I drained the fluid, which had minimal metal shavings, and flushed out the filter, which was in pretty good shape. You should be able to tell that the gears appear in excellent shape. New fluid and clean filter made zero difference in lifting ability. Therefore, I can't imagine it being anything other than the pump.

Everything I read said I'd need to split the tractor in order to remove the pump if the tractor was fitted with Multipower, but I'm just not setup to do that safely. Therefore, I tried it anyway. In order to even have a chance, I had to remove the small MP pump that sits to the front left of the housing, attached to the main hydraulic pump. Since it just pumped fluid up and right back out into the housing, I saw no harm. It got down to a couple of millimeters (not kidding) but I was able to wiggle it out. Made my day.

You should be able to tell in the pictures that the MP pump attaches to the main pump by bolting onto a heavy piece of angled iron that is bolted onto the main pump itself. There are NO line/fluid attachments between the two. The small pump has a gear in the back that is driven by the large gear in the back of the main pump. It is now rendered useless, and I don't intend on reattaching it. Here's the heart of my issue... This is the first time I've ever taken a tractor apart like this (thank goodness for the internet and the simplicity of old, reliable equipment) and I have no idea how to really assess what kind of shape the interior workings of this pump are in. The pump itself looks great (damage/wear-wise), but that, of course, doesn't determine functionality.

Ultimately, here are my questions:

1. Is there any reason why I couldn't leave the old MP pump off?

2. What am I looking for as far as signs of wear in my pump?

3. Where do I draw the line between rebuilding (kits seem to be $175-250) or replacing ($400-900) the pump?

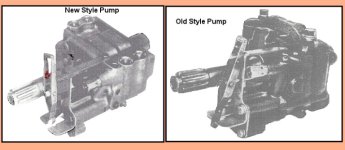

4. How do I determine exactly what pump I'm dealing with (there are 2-3 out there that apparently are slightly different, but those differences seem important)?

5. Who do y'all trust for these type of parts? I've used Stevens in Louisiana, Yesterdays Tractor and a couple others and been pleased...

6. Is there anything more gratifying than doing something like this that you've never done before and impressing your two young sons?

Thanks so much in advance... Now to try to attach these pictures...