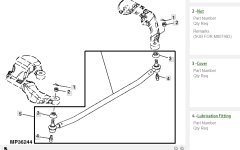

While putting new tires on my 2010-2305, noticed the right side tie rod ball is sloppy ( left still tight ). I just looked on Green Farm. List for $602

LVA803708

Has anyone ever replaced or even repaired ? Maybe a cheaper source.

It drives like new, never would have noticed except mounting tire and felt the slop. Thanks much for any insight or response. Bill

LVA803708

Has anyone ever replaced or even repaired ? Maybe a cheaper source.

It drives like new, never would have noticed except mounting tire and felt the slop. Thanks much for any insight or response. Bill

. I’ll follow up on my post with my fix eventually. Thanks again.

. I’ll follow up on my post with my fix eventually. Thanks again.