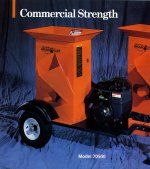

This thread struck up some interest as I just finished up on some chipping and shredding. Son and I own a older BearCat 70500

chipper/shredder, a towable model and has the opt blower. It's about 20 yr old and hasn't been used that much. Original cost $3500.

I find the design and build leave something to be desired. Accessing the

chipper blades is a 2 man job as your arm has to be down in both chutes. It is a long reach and hopefully you don't drop a wrench inside. Needed to sharpen the

chipper knives and noted out of the 4 knives on the flywheel, typ only 2 are used as the second pair only come into play on large dia branches/trunks.

There are clearance "chutes" behind the

chipper blades and IMO they are not large enough as they can and do get plugged with chips and as long as they are plugged, not chipping takes place.

Lots of metal and weld fatigue. The belt guard held in place with 3 mounting brackets on the side and had to re-weld one before using this time. Also had to weld in several places on the

chipper chute.

Chipper chute weld have partially failed where the chute attaches to main frame. Slightly below that there are signs of metal fatigue, i.e. 6" long crack. After use, found another 2 seam welds on the chute had failed and another bracket for the belt guard failed.

Chipper is kept under cover and paint is still in good shape so I doubt these failures are due solely to exposure.

IMO the blower is a must if you are running a lot of stuff through the machine. You don't want to be interrupted frequently to move either the

chipper or the chips.

Maybe newer model have changed and hopefully areas that are prone to failure due to stress have been addressed. For a machine that cost this much, having failures of materials and workmanship isn't encouraging.