OP

joshuabardwell

Elite Member

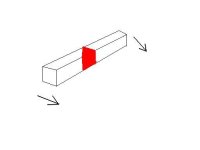

If you can heat these areas red hot, and use a spray bottle of water to cool the heated zone. The material must be cool to the touch before re-heating. Remember if you can feel heat with your hand, the material is still moving!

I think the rapid cooling is another component that I was missing. But I don't spray cold water on my welds, and they still warp the metal. I can't figure what's different between the two examples. Is it just that the welds are so much hotter?