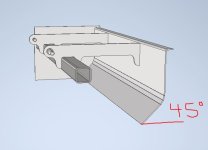

I attached image of ski idea I'm thinking also.

I have had the same thought, making it a land plane that can capture some amount of dirt.

Then I came across a Craigslist box blade for cheap that had a hinged rear blade so it was a great “cutter” but not as good at smoothing since one couldn’t ride on the rear fixed blade, it would just swing up and you were back to cutting.

I wound up removing the 3pt, teeth and blades from it and welding on sides and using 3/8” x 6” angle to make a land plane. It beats a box with skis for smoothing by a mile. The ball on the back is for a water filled roller to push the rocks back into the dirt.

I made cuts where the red lines are.

I also made it where I could adjust the blades up and down, from the replaceable wear edges On the bottom. The blades are tilted forward for an angle slightly less than 45 deg from vertical.

That said, those don’t move dirt very well from one location to another as it rolls over the blades.

Fast forward a couple years and I had piles of crushed concrete I needed to smooth out at the house and I made this using the box.

I used the electric trailer Jack as a linear actuator at the house because I was using a machine that had a fixed hitch height, so it was the only way I could control blade height, I haven’t plugged it in since I took it to the farm, I just use a 3pt draw bar. It allows a more precise depth of cut than a box and a more level release but will carry more material from one spot to another than a landplane.

The piviot in the rear is where the blade mounted and I came up with another I had to cut down for the inside.

So those came from my least favorite of 3 box blades but now that I have them, I don’t use the ones I favored much. For the most part road/trail maintenance is what I am doing.