<font color="blue"> OFFFF to Harbor Freight!. You know tools are cheap when they sell them by the pound. </font>

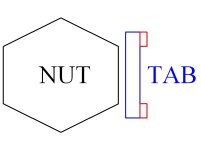

When I was trying to pull the hub of my PT-425's leaking wheel motor last year, I hied on down to Harbor Freight and bought the biggest hub puller they had in stock, which happened to be part of a set.

Once I got home, I assembled the puller and placed it on the hub. Well, I cranked and cranked and cranked and cranked on the puller nut, until finally there was this tremendous bang. Parts and pieces flew, birds departed the rafters, and a feral cat 500 yards away headed for the hills. After inventorying my extremities, checking my vision, and finding no blood evidence, I picked up the remains to return to Harbor Freight with the rest of the set. It was only then that I noticed the country of origin labeling on the box. "Made in India," it read.

From now on, I'm sticking with the good stuff from China. /forums/images/graemlins/grin.gif /forums/images/graemlins/shocked.gif /forums/images/graemlins/laugh.gif