Willl

Elite Member

Every time I see these SSQA, always think the lock pins are 180 out.

By the way, ktm010, nice fab job.

By the way, ktm010, nice fab job.

Every time I see these SSQA, always think the lock pins are 180 out.

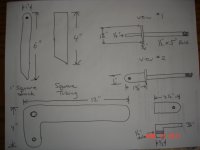

Here is a hyd and an electric locking setup

ohhh. i likes the hydraulic latching system........now i know what my next project is going to be.

There is no doubt that a hydraulic coupler is nice but it is a real PIA if it freezes in the winter, you need to get creative to thaw the thing out and thats no fun in a driving snow and its 10 degrees outside.

Even modest hydraulics should be able to break any reasonable coat of ice and snow.There is no doubt that a hydraulic coupler is nice but it is a real PIA if it freezes in the winter, you need to get creative to thaw the thing out and thats no fun in a driving snow and its 10 degrees outside.