You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

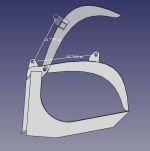

Grapple project OPEN SOURCE

- Thread starter polemidis

- Start date

/ Grapple project OPEN SOURCE

#11

Once you run the bill of materials to build a commercial quality product you'll find that doing it it strictly for cost savings doesn't make a lot of sense. Pins, cylinders, hoses, couplers, steel, welding wire, gas, plasma tips, etc all add up. OEMs get volume discount on materials that the general public can't replicate. Don't get me wrong, I'm all for building stuff but it usually works out cheap(er) because I use scrap materials, used or surplus cylinders, etc. Plus I can tailor the design exactly to my needs be it lighter, wider, stronger, etc than commercially available tools. With an "open source" design or a few similar designs you make compromises to satisfy differing requirements which drive the cost back up.

I wish you good luck with your venture.

You may be right... But I LOVE to CAD!!

Thank you for your comment.

rswyan

Super Member

- Joined

- May 12, 2004

- Messages

- 9,779

- Location

- Northeast Ohio

- Tractor

- Kubota B2910, Cub Cadet Pro Z 154S, Simplicity 18 CFC, Cub Cadet 782

http://www.tractorbynet.com/forums/build-yourself/320507-root-rake-grapple-kubota-b2910.html

Unfortunately the CAD files were lost when a hard drive took a dive ...

Unfortunately the CAD files were lost when a hard drive took a dive ...

LD1

Epic Contributor

If you are wanting to design and build a grapple because you cannot afford a new one.....you may get the designing done but you still arent gonna build one because you wont be able to afford it.

Same way with alot of other implements, and a pretty common one is a log splitter. You just cannot build one for less money than you can buy one for UNLESS you already have some of the material.

I can buy a good functioning grapple that will do everything you can ask a tractor with 1800# lift to do.....for $1100 all day long.

Building a one-off grapple is gonna cost you that much, in material.....then you are gonna be working on it for a good week cutting and welding and fitting parts.

I am all for building your own stuff. It gives you something to be proud of. But just want you to realize it isnt going to be a cost savings. So if that is your sole motivator....quit while you are ahead.

Now if you like projects, and enjoy being in the garage planning, laying out, cutting, welding, painting, etc. And dont mind doing all that work for no savings at all.....and strictly just to be able to say you built "that".....then go for it.

Same way with alot of other implements, and a pretty common one is a log splitter. You just cannot build one for less money than you can buy one for UNLESS you already have some of the material.

I can buy a good functioning grapple that will do everything you can ask a tractor with 1800# lift to do.....for $1100 all day long.

Building a one-off grapple is gonna cost you that much, in material.....then you are gonna be working on it for a good week cutting and welding and fitting parts.

I am all for building your own stuff. It gives you something to be proud of. But just want you to realize it isnt going to be a cost savings. So if that is your sole motivator....quit while you are ahead.

Now if you like projects, and enjoy being in the garage planning, laying out, cutting, welding, painting, etc. And dont mind doing all that work for no savings at all.....and strictly just to be able to say you built "that".....then go for it.

mike69440

Elite Member

- Joined

- Jun 2, 2005

- Messages

- 3,089

- Location

- Central NH (God's Country)

- Tractor

- 1984 Kubota B7200D (Sold 2015,) 2005 L39 Kubota, 2006 RTV 900 1997 Komatsu PC75UU2E w/ Thumb & Blade, 2013 Mahindra Max28XL Shuttle

I built have designed my own stuff, and other than the satisfaction and I'm not discounting that, it is a total time and $ waste. For $1,500 or less you can by a very nice new grapple (ebay, etc) and if you want the best there is Wicked.

I rather do seat time.

If you like the fun of it, design your product, and bounce it of Wicked, etc with a good legal NDA.

I rather do seat time.

If you like the fun of it, design your product, and bounce it of Wicked, etc with a good legal NDA.

I built my own front end loader for a garden tractor. Including design revisions, changes, broken parts while learning etc., even scrounging like mad to save costs, I spent more than what it would have cost me to buy ALL the garden-tractors-that-already-had-loaders on craigslist that showed up in the same time period. As someone who likes to play with cad and build things, I still had fun and consider it worthwhile, but saving money was not a goal I met. Oh, and the initial big project that drove me to start building it? Satisfied by renting a tractor-loader-backhoe for a day for under $200.

Going from your own design to the first really working product is called "prototyping", and most people who do it budget about 10x the cost of the final product.

There is a middle ground, which is project plans that have already been tested and built. There is a set of grapple plans on CADplans Corporation - Where you can find designs, tips and order information to build your own backhoes, diggers and MORE! and as a bonus, they are also members of the forum.

Going from your own design to the first really working product is called "prototyping", and most people who do it budget about 10x the cost of the final product.

There is a middle ground, which is project plans that have already been tested and built. There is a set of grapple plans on CADplans Corporation - Where you can find designs, tips and order information to build your own backhoes, diggers and MORE! and as a bonus, they are also members of the forum.

The big problem with design is that it's so easy to design the whole thing. Which is the last thing you want to do to save money.

First, find a part that is close to being what you want. A bucket, a set of forks, a bale spear, a carry-all, something like that. And a pile of scrap and some tools (welder, torch or plasma, angle grinder(s), sawzall, drill press), and modify the thing until it resembles what you want. Tweak, use, break, fix, modify, use some more. That will get you something you can use relatively fast and cheap.

But it's not something that fits well in a computer model, because it takes too long to model all the bits and pieces of parts and scrap, when you can just work 1:1 real time.

Where the computer modeling does save you time is little spot models of "I need to attach this to that, if I put the pivots here and here, will I have good range of motion, will I make good use of the power of hydraulic cylinder, and can I avoid having to buy another stick of flat bar?"

I end up doing a lot of these little model sketches to "pre-test" design tweaks and changes.

But none of this really ends up being something anyone would be really willing to distribute (or download) as any sort of public use model.

To get the most use of this forum, just dig into your build. Show your sketches, discuss your changes, take pictures as you go. Someone looking to do something similar may take a lesson you learned here, and a nifty design idea there and incorporate it into their build...which will be different as fits their available materials.

I'll give you another example: my brother is clearing up his overgrown back yard, and figured out that while the set of forks he had could work if modified as a grapple, what he really needed was a root rake. 6 or 8 teeth hacked from plate with a torch and welded on at an angle to the bottom fork frame tube and he had a root rake for cheap money...but how many people are going to have that model fork frame on that tractor and need a root rake?

First, find a part that is close to being what you want. A bucket, a set of forks, a bale spear, a carry-all, something like that. And a pile of scrap and some tools (welder, torch or plasma, angle grinder(s), sawzall, drill press), and modify the thing until it resembles what you want. Tweak, use, break, fix, modify, use some more. That will get you something you can use relatively fast and cheap.

But it's not something that fits well in a computer model, because it takes too long to model all the bits and pieces of parts and scrap, when you can just work 1:1 real time.

Where the computer modeling does save you time is little spot models of "I need to attach this to that, if I put the pivots here and here, will I have good range of motion, will I make good use of the power of hydraulic cylinder, and can I avoid having to buy another stick of flat bar?"

I end up doing a lot of these little model sketches to "pre-test" design tweaks and changes.

But none of this really ends up being something anyone would be really willing to distribute (or download) as any sort of public use model.

To get the most use of this forum, just dig into your build. Show your sketches, discuss your changes, take pictures as you go. Someone looking to do something similar may take a lesson you learned here, and a nifty design idea there and incorporate it into their build...which will be different as fits their available materials.

I'll give you another example: my brother is clearing up his overgrown back yard, and figured out that while the set of forks he had could work if modified as a grapple, what he really needed was a root rake. 6 or 8 teeth hacked from plate with a torch and welded on at an angle to the bottom fork frame tube and he had a root rake for cheap money...but how many people are going to have that model fork frame on that tractor and need a root rake?

If you are wanting to design and build a grapple because you cannot afford a new one.....you may get the designing done but you still arent gonna build one because you wont be able to afford it.

Same way with alot of other implements, and a pretty common one is a log splitter. You just cannot build one for less money than you can buy one for UNLESS you already have some of the material.

I can buy a good functioning grapple that will do everything you can ask a tractor with 1800# lift to do.....for $1100 all day long.

Building a one-off grapple is gonna cost you that much, in material.....then you are gonna be working on it for a good week cutting and welding and fitting parts.

I am all for building your own stuff. It gives you something to be proud of. But just want you to realize it isnt going to be a cost savings. So if that is your sole motivator....quit while you are ahead.

Now if you like projects, and enjoy being in the garage planning, laying out, cutting, welding, painting, etc. And dont mind doing all that work for no savings at all.....and strictly just to be able to say you built "that".....then go for it.

You may be right, but I would like to see the actual cost in the Bill of Materials. No offense, but your sense and experience (and a lot of people aggree with you as I see in the comments) is that I am not going to save -which is subjective-, my sence (and inexperience

That being said, the cost is the most important factor. The 2nd motivation is that it will be available to anyone to replicate/imrove alter. Which will make sense only if it is cheaper than the commercial model of course!

Anyway, I am getting closer.

I had decided to go with a simple design with flat bars for the tines and gussets for reinvorcment at the corner. But after researching the forums I found a project where a guy cut out nice curved tines with a handheld plasma torch. So I reconsidered and stuck to the initial design. I understand that the freehand cut will not generate identical tines but I think it not so much of importance. Am I correct?

Now on the other hand, would a few pics give you some ideas of things that you might do that are similar, without getting too specific?

View attachment 526196View attachment 526198View attachment 526197

View attachment 526196View attachment 526198View attachment 526197