There was a guy on another forum who made all his machines using "cardboard assisted design."

He would make all his parts full size, on the machine, with light weight boards, cardboard, and nuts and bolts. For a cylinder, he would have two boards, one with holes at the "retracted" distance, and one with holes at the "extended" distance. He would take notes with a marker directly on the parts. You can learn stuff from doing that that you might miss other wise, like "will the bucket hit the hood when the boom goes up?"

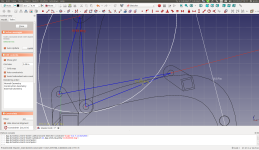

Computers are fun, but they are not always the best way, or the only way.

He would make all his parts full size, on the machine, with light weight boards, cardboard, and nuts and bolts. For a cylinder, he would have two boards, one with holes at the "retracted" distance, and one with holes at the "extended" distance. He would take notes with a marker directly on the parts. You can learn stuff from doing that that you might miss other wise, like "will the bucket hit the hood when the boom goes up?"

Computers are fun, but they are not always the best way, or the only way.