polemidis

Gold Member

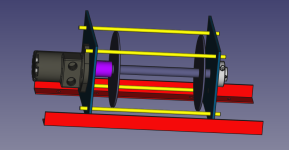

Hello, I am willing to buy this motor for a hydraulic winch. 22.8 cu in White Hydraulic Motor 5375A582AAAAE | Low Speed High Torque Hydraulic Motors | Hydraulic Motors | Hydraulics | www.surpluscenter.com

I called their customer service, they have not idea how to connect it.

I also found this reference material for this motor http://www.crosshydraulics.com.au/f...kes/Spare Parts Breakdown/RE8.21_Declutch.pdf

What I want to do is to free unwind the winch when I want to go grab something, but also do hold the weight when I release the directional valve after pulling some weight

Obviously I want to only pull something, one direction on the motor

From my understanding I should TEE one Work Port on the motor with the Clutch Port of the motor to one work port of the Valve, and connect the other motor port to the other valve work port. Am i right? Has anyone experience with these? I do not see any specs on how much pressure the clutch port can take so I worry not to explode anything.

Thank you guys!

I called their customer service, they have not idea how to connect it.

I also found this reference material for this motor http://www.crosshydraulics.com.au/f...kes/Spare Parts Breakdown/RE8.21_Declutch.pdf

What I want to do is to free unwind the winch when I want to go grab something, but also do hold the weight when I release the directional valve after pulling some weight

Obviously I want to only pull something, one direction on the motor

From my understanding I should TEE one Work Port on the motor with the Clutch Port of the motor to one work port of the Valve, and connect the other motor port to the other valve work port. Am i right? Has anyone experience with these? I do not see any specs on how much pressure the clutch port can take so I worry not to explode anything.

Thank you guys!

Last edited: