jimmer2880

Platinum Member

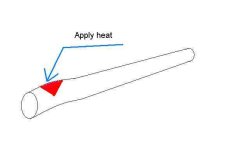

Aluminum can be heated and straightened easily but there is a fine line between when it's hot enough to bend and melting. When the aluminum starts to melt it doesn't do it in slow motion. It's kind of like "poof" and it's gone.

I found that it's a whole lot easier to find that spot where it bends, but doesn't melt by using MAPP gass instead of Oxy/Actelyne.

I'm no expert, but I've had to straighten my boat bimini top poles more than once