Hello everyone!

So, firstly, thanks for all the comments and support with this problem. I've finally had some time to dedicate to splitting the tractor to find out what exactly caused this massive leak.

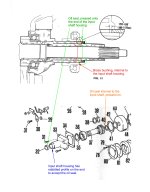

And, as you can see in the attached pic, the problem was pretty obvious the moment the light of day hit that input shaft. It seems the main seal has cracked apart, rather dramatically.

I wanted to make this posting to at least keep everyone updated on this, as I'm sure it's a bit of curiosity to some of you who enjoy seeing these kinds of things. It's not everyday we get to see a 50 year old tractor torn apart to inspect.

But also, I wanted to further ask the advice of all of you who have been so helpful and encouraging to see if there were some further thoughts on things I should do while I've got this open. Of course, I'll need to correctly identify and get a hold of the seal that has broken, but also I'd like to get a little further in there behind the input shaft cover and replace the other seals and split washers that appear there on the parts breakdown.

And there has been one comment in favor of replacing the clutch, and one comment in favor of cleaning the clutch. So, any further comments regarding the clutch? I know for a fact as I was using this to finish my fall work(about 3 hours of total plowing after I discovered the leak out the weep hole) that hydraulic/tranny oil must have surely got on the clutch as it was sputtering out the top of the bell housing where you can see the flywheel. So, with that in mind, I'm assuming the clutch has got oil all over it. But I suppose a good dousing with clutch/brake cleaner could take care of that.

And while I like the idea of preventative maintenance, especially while I've got it open... I was pleasantly surprised at how easy it was to open it up. Most of the time consumed in the process so far was fabricating the wheel stands to hold the rear of the tractor up as I separated it. So, now that is done, I don't see it as such a big chore to open it up again in the future should other issues arise, maybe an hour total of bolts and wiring removal to get that part done.

I'm located in Europe in Czech Republic, does anyone have any idea about how to figure out the correct Massey part numbering for the seals I need to get a hold of? The parts breakdown I have is a full featured shop manual with about 1000 pages, but the parts breakdown doesn't give the Massey numbers, they're only index numbers(1, 2, 3 etc...) for identification on the drawing.

Also, regarding the hydraulic oil... I have a neighbor who is farming on a much larger scale who uses hydraulic oil by the barrel and can give me some for this job to refill when I'm done. It's Shell Spirax S4 TXM. Would this be alright to use or do I need to seek out some other hydraulic/tranny oil for this 1965 MF 165?

Thanks everyone!

Will of course keep everyone updated as this progresses.