Sorry for the delay for anyone following this thread but I finally got my FEL working!

I managed to find a new front pulley that's designed to work with the flange adapter.

After removing the battery & tray, draining & removing the radiator.....all the time with mosquitos biting me...

I purchased a 46 mm deep impact socket & 1/2-3/4 adapter I broke my 1/2 drive flex bar trying to remove the pulley nut.

Next I used my 1/2" Craftsman ratchet & a long pipe but the clutch would slip when loosening.

Next I installed a vice grip on the pulley only to have a piece break off as the pulley is cast iron & brittle.

Next trip.....I purchased a 3/4" drive 18V Makita impact wrench & got the pulley nut off in just a few seconds.

While using my 3 armed pulley removal tool I broke off another chunk of the pulley.

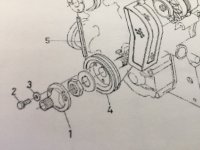

I saw a picture of a different removal tool that uses 2 bolts threaded into the threaded holes in the pulley.

I eventually got the pulley to start sliding off the crankshaft end only to find the front casting did not have enough room for the pulley removal.

It appears I would have to remove the whole front axle & subframe at the front of the engine to replace the pulley.

Plan B...

I took my damaged PTO shaft to a local machine shop & asked for a new spline to be welded in place of the old one but 1/4" longer

to take advantage of the undamaged crankshaft splines.

So far so good, I tapped the new coupler in place with some lithium grease inside & everything mated up perfectly.

I gave the FEL a good workout to the point of the back wheels up in the air & still works.

Forgot to mention....before I installed the PTO shaft I installed a new fan belt as I can't change it later.

I know the pulley looks like **** but seems to work just fine even with the missing chunks as its not bent or anything.

View attachment 560165

I still have the the new pulley, bolts & flange if this repair doesn't last but hopefully I wont need them.

View attachment 560164