Thanks to Jrasband for the details.

Thanks to Kevin Launcher for the Youtube video.

Thanks to Ky1200 for the details on the throttle cable and cable stopper.

- I started off by calling for help from the dealer to check for any obvious reasons for the Regen complete failure, their mobile mechanic with a computer did a manual regen at 27K rpm, brought down the soot level from 87% to 20% in 25 minutes. The Warning and DPF lights were gone after the manual regen. He didn’t see any error code or any obvious reason for the failure earlier.

- With no error or fault lights to start with, I did everything Kevin L. had said in his video. The first filter just slid out, but there was no way to get the second filter out without cracking it. For whatever reason if anyone wants to save the second filter, there is a band of cloth/fibre like material as the outer layer of the honeycomb, this band is glued to the inner walls of the dpf chamber, if you can have a thin and flexible blade 3 to 4 inches long and carefully run in between the band and the steel chamber wall, you could it save it.

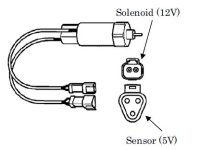

- Used the same Oregon 60-522 control cable and a set of Dorman 03336 cable stop assortment from amazon, that Ky1200 had mentioned.

- Set the low rpm at 9K-10K, left the high rpm at the factory settings.

- I turn the key ON for the glow plugs to heat up, then turn the key OFF back to turn it back ON again to start the ignition. For whatever reason there is no power for ignition if I try the ignition without turning it OFF back after waiting for the glow plug to heat.

- At this stage when the engine is running, I just get the flashing Warning light and NO DPF lights or the beeping noise.

- I am guessing the DPF lights will come ON when it hits the next 4 hours auto regen cycle, I will give an update then. If anyone knows a way to stop it from going to the regen cycle hours count and the dpf lights permanently OFF, please let me know.

- For the first start there was some exhaust leak around the dpf chamber where the first filter was located, then it disappeared for the later starts or it is not obviously visible.

- Now the tractor sounds like a tractor and not like an aircraft.

- I also get AB04 error code on the display, which is Foot throttle sensor error, which I think is okay to ignore.

Thanks to ALL for sharing their experience here, with these details and help from my friend we were able to get it done before the winter cold.

Cheers.

Thanks to Kevin Launcher for the Youtube video.

Thanks to Ky1200 for the details on the throttle cable and cable stopper.

- I started off by calling for help from the dealer to check for any obvious reasons for the Regen complete failure, their mobile mechanic with a computer did a manual regen at 27K rpm, brought down the soot level from 87% to 20% in 25 minutes. The Warning and DPF lights were gone after the manual regen. He didn’t see any error code or any obvious reason for the failure earlier.

- With no error or fault lights to start with, I did everything Kevin L. had said in his video. The first filter just slid out, but there was no way to get the second filter out without cracking it. For whatever reason if anyone wants to save the second filter, there is a band of cloth/fibre like material as the outer layer of the honeycomb, this band is glued to the inner walls of the dpf chamber, if you can have a thin and flexible blade 3 to 4 inches long and carefully run in between the band and the steel chamber wall, you could it save it.

- Used the same Oregon 60-522 control cable and a set of Dorman 03336 cable stop assortment from amazon, that Ky1200 had mentioned.

- Set the low rpm at 9K-10K, left the high rpm at the factory settings.

- I turn the key ON for the glow plugs to heat up, then turn the key OFF back to turn it back ON again to start the ignition. For whatever reason there is no power for ignition if I try the ignition without turning it OFF back after waiting for the glow plug to heat.

- At this stage when the engine is running, I just get the flashing Warning light and NO DPF lights or the beeping noise.

- I am guessing the DPF lights will come ON when it hits the next 4 hours auto regen cycle, I will give an update then. If anyone knows a way to stop it from going to the regen cycle hours count and the dpf lights permanently OFF, please let me know.

- For the first start there was some exhaust leak around the dpf chamber where the first filter was located, then it disappeared for the later starts or it is not obviously visible.

- Now the tractor sounds like a tractor and not like an aircraft.

- I also get AB04 error code on the display, which is Foot throttle sensor error, which I think is okay to ignore.

Thanks to ALL for sharing their experience here, with these details and help from my friend we were able to get it done before the winter cold.

Cheers.

Last edited: