Fluid replacement is on the to do list for the weekend. The axle froze again. That front oil definitely needs to be replaced. All right I got another question for everybody. Took my battery off to charge it and noticed how rusted/corroded some of the leads were. Decided while I was at it I would pull the ground strap, hot wire to the solenoid, and solenoid off to clean all the posts/surfaces of corrosion/surface rust etc. to get a better/cleaner current to my starter.

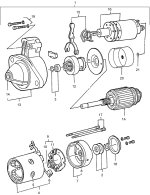

Well I may have bitten off more than I can chew with the solenoid. I've disassembled and replaced plenty of solenoids before (power sports) but this one was new to me. I made the ultimate mechanic sin of taking something apart and not remembering how it went back together. I am particularly baffled by the spring/plunger/actuator arm that goes down into the starter. Clearly I can see the plunger slot goes over the acuator arm but how does that dang spring go back in there? And which leads go to which post on the solenoid? Anybody got a diagram of exactly how they go back together? I wouldn't have pulled the solenoid knowing these internal parts would come out when I pulled it off the starter. I thought, like in power sports, it alone would come off as one easily replaceable unit and I would more easily be able to clean it's brass posts.

Thanks again to everybody, you guys have already been a big help!

Pics will be on the way. May take me a couple days but they will come!

Jonah

Well I may have bitten off more than I can chew with the solenoid. I've disassembled and replaced plenty of solenoids before (power sports) but this one was new to me. I made the ultimate mechanic sin of taking something apart and not remembering how it went back together. I am particularly baffled by the spring/plunger/actuator arm that goes down into the starter. Clearly I can see the plunger slot goes over the acuator arm but how does that dang spring go back in there? And which leads go to which post on the solenoid? Anybody got a diagram of exactly how they go back together? I wouldn't have pulled the solenoid knowing these internal parts would come out when I pulled it off the starter. I thought, like in power sports, it alone would come off as one easily replaceable unit and I would more easily be able to clean it's brass posts.

Thanks again to everybody, you guys have already been a big help!

Pics will be on the way. May take me a couple days but they will come!

Jonah