BirdmanColorado

New member

I have owned my Terramite T5C since 1999 having bought it at a rental surplus auction with about 1100 hours on it. Now (June 2020) it has over 2500 hours! I vaguely recall the steering always being hard, but in recent years (maybe it just me getting older??), I noticed the stiff steering as more of an annoyance, so I decided to investigate.

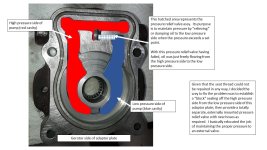

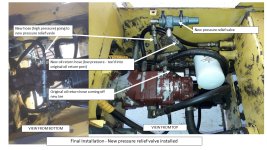

It appears that MANY Terramite T5C owners have issues with power steering. Apparently, power steering is a major weakness…if not the MOST significant failure point of older T5C loader/backhoes. Through forums like this one, I learned that the PS problem is either due to a failure in the steering column valve box, or the adaptor plate on the Eaton hydrostatic transmission.

Whatever the steering column valve box problem is apparently has to do with water freezing in the column tube, upsetting a seal near the steering box, and bingo….problems Galore erupt and show their ugly head. In my case, I did NOT suspect the steering column box because; 1. I could still steer the tractor (albeit hard), and; 2. My tractor is/was always garaged. The steering box still looks new. I REALLY suspected the problem was low/or no boost pressure.

I came upon this thread on TBN which REALLY helped tremendously to drill down to the problem. Posts by bd53bz2 were a gold mine and was the first one to nail the problem I had with my T5C. Subsequent posts from: Wdchyd, cstamm81, and ChippyMcGee provided FANTASTIC information on this forum.

I was so impressed and so grateful for this information, that I decided that I too should register on TBN and take the time to share what I learn and what I experience. THANK YOU bd53bz2, cstamm81, Wdchyd, and ChippMcgee for your information. Now allow me to pay-back some myself with much gratitude for this forum and the kind people who contribute.

More to follow.

It appears that MANY Terramite T5C owners have issues with power steering. Apparently, power steering is a major weakness…if not the MOST significant failure point of older T5C loader/backhoes. Through forums like this one, I learned that the PS problem is either due to a failure in the steering column valve box, or the adaptor plate on the Eaton hydrostatic transmission.

Whatever the steering column valve box problem is apparently has to do with water freezing in the column tube, upsetting a seal near the steering box, and bingo….problems Galore erupt and show their ugly head. In my case, I did NOT suspect the steering column box because; 1. I could still steer the tractor (albeit hard), and; 2. My tractor is/was always garaged. The steering box still looks new. I REALLY suspected the problem was low/or no boost pressure.

I came upon this thread on TBN which REALLY helped tremendously to drill down to the problem. Posts by bd53bz2 were a gold mine and was the first one to nail the problem I had with my T5C. Subsequent posts from: Wdchyd, cstamm81, and ChippyMcGee provided FANTASTIC information on this forum.

I was so impressed and so grateful for this information, that I decided that I too should register on TBN and take the time to share what I learn and what I experience. THANK YOU bd53bz2, cstamm81, Wdchyd, and ChippMcgee for your information. Now allow me to pay-back some myself with much gratitude for this forum and the kind people who contribute.

More to follow.