bob2299

Bronze Member

- Joined

- Dec 14, 2010

- Messages

- 67

- Location

- Canada Northern Ontario

- Tractor

- Bobcat ct230, 35 hp Massey Furgeson 3Cyl Diesel

hello I would like to build a PTO Winch, and maybe they already exist, what I am looking for is a Winch that has feel fall,

my worries, is once the cable is all the way in how does it stop, and if I want to let it free fall once it's got the weight on on it How do I do this. the weight would be 200 to 300 pound's I don't think it need's to be heavier, and that might be a little to heavy.

Now I have some Idea's thanks to some of your idea's, but I wanted to improve on them, now here is a portion of an idea I borrowed.

Run my PTO shaft back to a jackshaft with two bearings on it. Make another shaft with a winch drum on it. made out of pipe, with drum sides cut out of plate steel. Belt drive from the PTO shaft to the winch drum shaft. Leave the belt a little loose and use a tensioning idler pulley that is hand operated. I would install a Slip clutch on the PTO shaft so if my cable is all the way in and I did not release the lever fast enough the slip clutch would engage,

once my lever is release the cable would be free, to avoid back lash when the cable is set free, I would install a plate that pushes on the cable inside the drum with a little spring tension so the drum does not start un-rolling and make a big "birds nest" of cable.

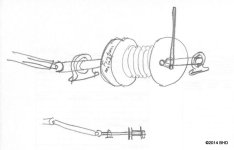

now can you adjust the tension on a slip clutch I was thinking of a WEASLER 1 3/8" X 6 SPL FRICTION CLUTCH, but does any one know if the tension can be adjusted on these clutches.

Now maybe I am over thinking, if this type of a winch already exist, and I can get a used one, it would have to be powered by my PTO, I would like to make a 3pt hitch Post pounder. and this would be the way to bring up the weight.

THNX.

my worries, is once the cable is all the way in how does it stop, and if I want to let it free fall once it's got the weight on on it How do I do this. the weight would be 200 to 300 pound's I don't think it need's to be heavier, and that might be a little to heavy.

Now I have some Idea's thanks to some of your idea's, but I wanted to improve on them, now here is a portion of an idea I borrowed.

Run my PTO shaft back to a jackshaft with two bearings on it. Make another shaft with a winch drum on it. made out of pipe, with drum sides cut out of plate steel. Belt drive from the PTO shaft to the winch drum shaft. Leave the belt a little loose and use a tensioning idler pulley that is hand operated. I would install a Slip clutch on the PTO shaft so if my cable is all the way in and I did not release the lever fast enough the slip clutch would engage,

once my lever is release the cable would be free, to avoid back lash when the cable is set free, I would install a plate that pushes on the cable inside the drum with a little spring tension so the drum does not start un-rolling and make a big "birds nest" of cable.

now can you adjust the tension on a slip clutch I was thinking of a WEASLER 1 3/8" X 6 SPL FRICTION CLUTCH, but does any one know if the tension can be adjusted on these clutches.

Now maybe I am over thinking, if this type of a winch already exist, and I can get a used one, it would have to be powered by my PTO, I would like to make a 3pt hitch Post pounder. and this would be the way to bring up the weight.

THNX.