OK. ... The female spline just slips over the male and cannot escape because of the bolt in the shaft groove. This is identical to the connections I often see on the tractor PTO stub - the old push button style. The spring loaded pin operated by the button does the same thing as your bolt. TOTALLY trouble free in my experience, but on the tractor and on the 6 spline 540 pto stub. Your situation is worse in several ways:

,,,1] The coupling is on the implement and bushogs can jump around a lot, all impulse coming thru the gearbox,

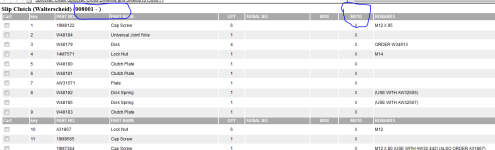

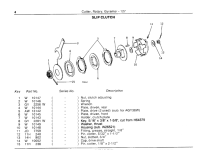

,,,2] The slip clutch presents an overhung load on the coupled joint,

,,,3] The floating joint is free to move and wear,

,,,4] You have a fine spline [presumed the std 1-3/8 X 21 tooth used for 1000rpm?]

Altho the 1000 rpm is great for transmitting a lot of power the use of fine spline is unfortunate in that they cant put up with much wear and still work optimally. ... And your case of a floating [not clamped] fine spline supporting overhung loading in the face of some vicious vibration is all bad.

,,,If your MX10 is the same as others, and your use is typical, then why dont they all show what youre seeing?

:confused3: MAYBE that shaft is bent a little. ... also, from your bolt pic, the bolt wear is quite close to the threads and their small root is vulnerable to notch failure. A longer shank with just enuf thread to tighten the nut would be more durable. Also, using the largest bolt that will pass thru would be an improvement.