You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

smaller backhoe bucket

- Thread starter charlz

- Start date

/ smaller backhoe bucket

#21

Seon

Silver Member

Admirable that you made the bucket. Being retired, I had high hopes to do the same thing and with most the honeydo's done, last spring, I went out and bought a 5th wheel travel trailer for the wife and I to do some camping. Then while out camping, I decided to do some fishing which led to buying a boat. So it left little time to build a smaller bucket. I searched the net, and found an outfit that built one from my drawings. They fabricated, welded and shipped the 12" bucket for $465. I haven't had a chance to try it out as yet...been fishing but hopefully soon, I'll get back to the tractor to play  .

.

patrick_g

Elite Member

John, That bucket design is of course superior to my idea and requires no extra hydraulics. I guess I had the right idea but not a well thought through solution. The relationship to the position of the bucket emptier vs curl angle could be made to be quite non-linear so the flap didn't move much till curled nearly to the limit and then pop out.

I like it!

Thanks John.

Pat

I like it!

Thanks John.

Pat

SkunkWerX

Platinum Member

Nice JOB!! Beautiful.

You should notice a measureable difference when digging, using the narrower set-up, perfect for trenching.

Action pics??

You should notice a measureable difference when digging, using the narrower set-up, perfect for trenching.

Action pics??

SkunkWerX said:Nice JOB!! Beautiful.

You should notice a measureable difference when digging, using the narrower set-up, perfect for trenching.

Action pics??

Thanks! The cutting edge material won't be here till about this time next week so action pics will have to wait

As others have suggested I am going to try it without any teeth and go from there.

Charles

RedDirt

Gold Member

- Joined

- Dec 4, 2007

- Messages

- 469

- Location

- Northern Idaho

- Tractor

- Kubota BX23, Wards 16HP HST Garden Tractor, (previous) D2 Logging Cat

patrick_g said:John, That bucket design is of course superior to my idea and requires no extra hydraulics. I guess I had the right idea but not a well thought through solution. The relationship to the position of the bucket emptier vs curl angle could be made to be quite non-linear so the flap didn't move much till curled nearly to the limit and then pop out.

I like it!

Thanks John.

Pat

patrick g,

I am also building (going to this winter) a narrow bucket. Looked at the extractor flap at Harford Mfg link from pycoed's post. From the Harford photo I can't quite make out the geometry of the flapper "actuator" lever, pin locations, etc. I like your idea of a not-quite-linear setup. Any way you could post a rough sketch of the mechanics?

patrick_g

Elite Member

Red Dirt, I'm sorry if I led you astray. I have no drawing or completed design but while reading the post to which I replied a couple methods came to mind.

One was a cam and the other was a bellcrank and control horn with pushrods.

First the cam: if you cut out a steel cam to be attached to the bucket and have the cam follower actuate the flapper then the cam can be flat until slightly before the end of travel of the curl. Then as you begin to reach the end of travel the follower will ride up on the slope of the cam and activate the flapper. This would probably need a spring to keep follower in direct contact with the cam and to keep the attached flapper out of the way till the curl action energized it.

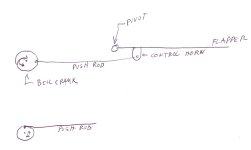

Bellcrank and control horn approach:

If the curl action moved a pushrod connected to a bell crank and a second pushrod connected to the bellcrank activated the flapper with a control horn then adjusting the radii of the connections of the pushrods and the location of the bellcrank and length of the control horn would allow you to essentially get only a little motion from the output pushrod until the bellcrank rotated quite a ways through its travel and then when the proper geometry was achieved the output pushrod would rapidly start to actuate the flapper connected control horn.

Since my bellcrank description may be less than complete, concise, and communicative I have included a sketch to completely eliminate any ability to understand my meaning.

In the sketch you can see that rotary motion (bucket curling motion) when moving the attachment point of the push rod in the upper portion of the sketch will not move the pushrod very much from about 2-4 O'clock position. Note in the lower partial sketch just showing bellcrank and pushrod with the attachment point of the pushrod at or near the 12:00 position that the pushrod will be moved the most.

By adjusting the radius at which the pushrods (both at the bellcrank and the control horn) are attached you regulate the angular to linear motion ratios which as seen in the drawing are non linear. Of course you would want the least range of motion of the bellcrank on the flapper to be in the range of rotary motion when the curl was not to near the limit (when you want the flapper to expel dirt)

I have built mechanical systems just like this for non-linear rotary to linear to rotary motion conversion but NOT A BACKHOE BUCKET. It was to apply elevator control for an airplane.

I suspect the equipment already doing this sort of thing has worked out all the design issues and would be a far better starting place than my brute force and awkwardness.

Pat

One was a cam and the other was a bellcrank and control horn with pushrods.

First the cam: if you cut out a steel cam to be attached to the bucket and have the cam follower actuate the flapper then the cam can be flat until slightly before the end of travel of the curl. Then as you begin to reach the end of travel the follower will ride up on the slope of the cam and activate the flapper. This would probably need a spring to keep follower in direct contact with the cam and to keep the attached flapper out of the way till the curl action energized it.

Bellcrank and control horn approach:

If the curl action moved a pushrod connected to a bell crank and a second pushrod connected to the bellcrank activated the flapper with a control horn then adjusting the radii of the connections of the pushrods and the location of the bellcrank and length of the control horn would allow you to essentially get only a little motion from the output pushrod until the bellcrank rotated quite a ways through its travel and then when the proper geometry was achieved the output pushrod would rapidly start to actuate the flapper connected control horn.

Since my bellcrank description may be less than complete, concise, and communicative I have included a sketch to completely eliminate any ability to understand my meaning.

In the sketch you can see that rotary motion (bucket curling motion) when moving the attachment point of the push rod in the upper portion of the sketch will not move the pushrod very much from about 2-4 O'clock position. Note in the lower partial sketch just showing bellcrank and pushrod with the attachment point of the pushrod at or near the 12:00 position that the pushrod will be moved the most.

By adjusting the radius at which the pushrods (both at the bellcrank and the control horn) are attached you regulate the angular to linear motion ratios which as seen in the drawing are non linear. Of course you would want the least range of motion of the bellcrank on the flapper to be in the range of rotary motion when the curl was not to near the limit (when you want the flapper to expel dirt)

I have built mechanical systems just like this for non-linear rotary to linear to rotary motion conversion but NOT A BACKHOE BUCKET. It was to apply elevator control for an airplane.

I suspect the equipment already doing this sort of thing has worked out all the design issues and would be a far better starting place than my brute force and awkwardness.

Pat

Attachments

RedDirt

Gold Member

- Joined

- Dec 4, 2007

- Messages

- 469

- Location

- Northern Idaho

- Tractor

- Kubota BX23, Wards 16HP HST Garden Tractor, (previous) D2 Logging Cat

Pat, thanks for the sketch. You've given me some ideas I'll need to chew on when I have more time. I kinda like the cam concept; less moving parts in a confined space. Maybe I'll start a design/build thread later on an "ejector bucket" as charles' fine work is beyond this point and this ejector stuff is getting off his topic.

2manyrocks

Super Member

- Joined

- Jul 28, 2007

- Messages

- 7,326

Charlz, did you cut out the sides and the parts that attach the bucket to the backhoe with just an angle grinder?