ptsg

Super Member

I've thought about it but it would only work for non PTO powered implements. Anything that uses a PTO, will just get in the way.

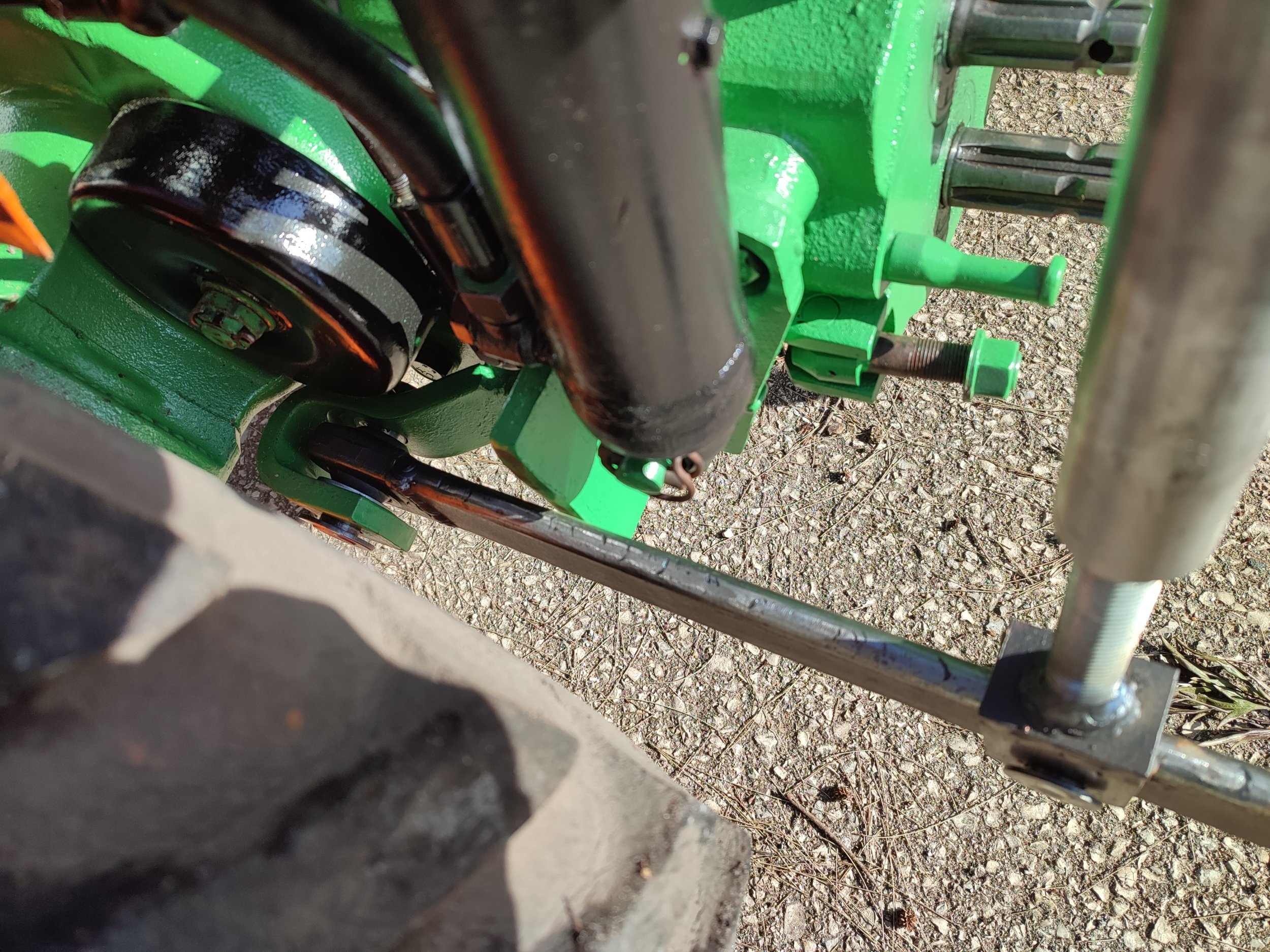

The PTO gearbox on this tractor bolts on like an add on, so it sticks way out the back. Adding to that, the PTO shaft that actually gets used, sits too low. It's very easy to get the PTO shaft on a bind due to excessive angles and that also puts the PTO shafts almost inline with the arms.

Shims to adjust the spacing between the arms and the vertical sliding plate are my only option right now.

The PTO gearbox on this tractor bolts on like an add on, so it sticks way out the back. Adding to that, the PTO shaft that actually gets used, sits too low. It's very easy to get the PTO shaft on a bind due to excessive angles and that also puts the PTO shafts almost inline with the arms.

Shims to adjust the spacing between the arms and the vertical sliding plate are my only option right now.