D

Deleted member 371759

Guest

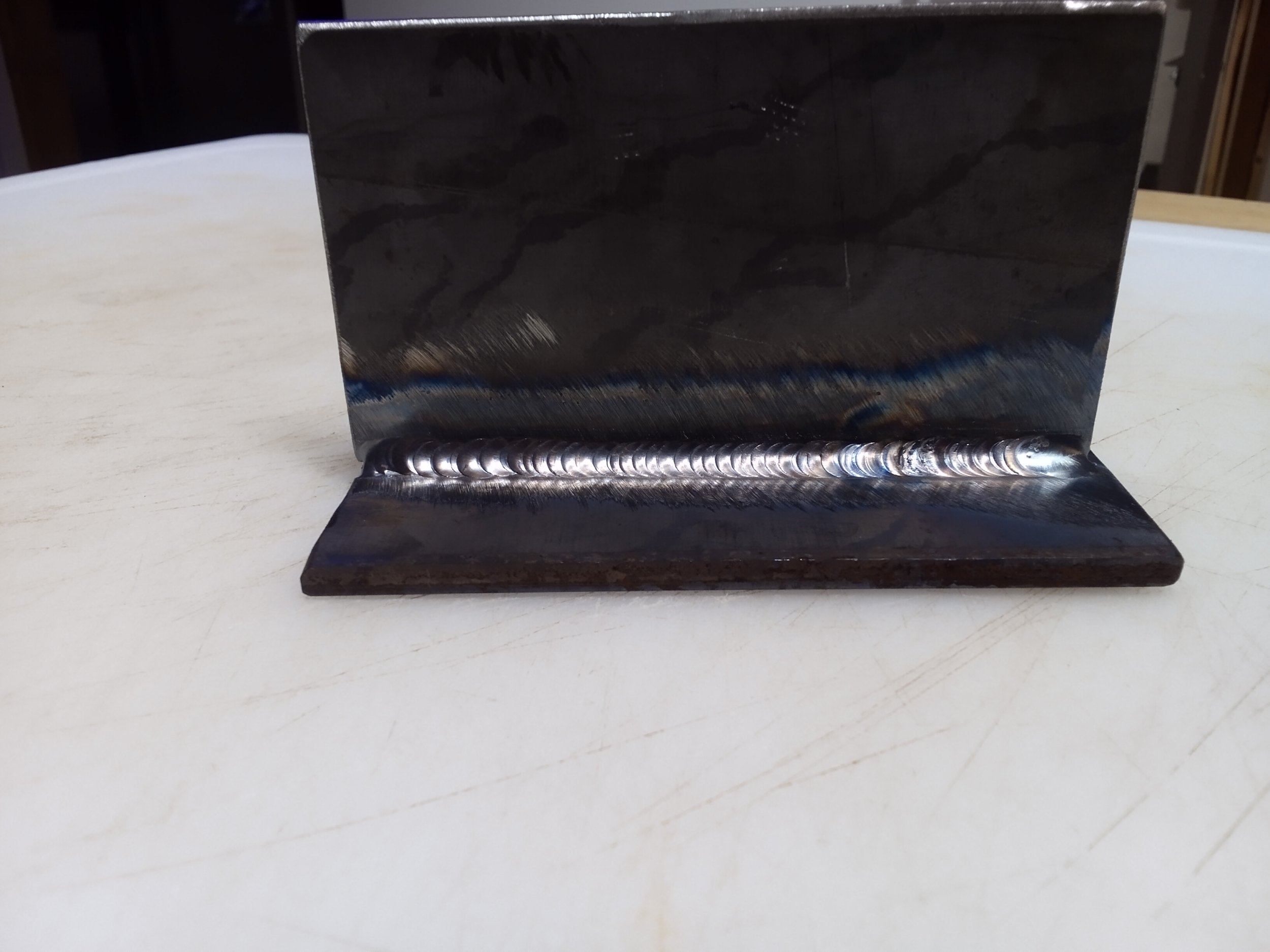

Some TIG welding practice. Feel free to tell me how terrible I am. 3/32 2% lanthanated tungsten, 160 amps. 11/64th hot rolled steel . 15cfh argon. Stubby #8 gas lens.

I may have taken the filler out of the argon shielding.A little ruff at the beginning, very good in the middle (steady and constant) but then there is some porosity at the end... I am sure you know what you did wrong at the beginning but do you know what went wrong at the end ?

You are doing good, keep it up and do more of what you did in the middle.