How heavy was the backhoe? Did it have outriggers? Wonder if someone abused the rear end in the course of using my backhoe...

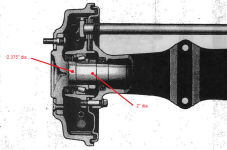

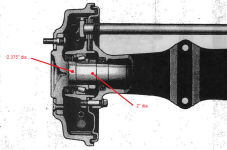

My quest for info on the 3780 vs. 3795 cone hasn't produced much. I talked to Timken, NTN (who bought Bower), SKF, and even Agco. Speaking of the latter, I think they need to rename "Agco Answers" to "Agco Pawns You Off On Your Local Dealer", because that's what they've done to me every time I've called them. Oh well, I'll probably just get one of the 3795s and make sure it has the right frontface radius on it. Here's a cutaway view that shows the bearing pretty well. I labeled the bearing and outer seal diameters:

My sandblaster is currently down - stripped everything off it so I could put a real hopper on the bottom. Thread about it here:

hopper for blast cabinet

Gonna get back to blasting parts once I get that on there.

My quest for info on the 3780 vs. 3795 cone hasn't produced much. I talked to Timken, NTN (who bought Bower), SKF, and even Agco. Speaking of the latter, I think they need to rename "Agco Answers" to "Agco Pawns You Off On Your Local Dealer", because that's what they've done to me every time I've called them. Oh well, I'll probably just get one of the 3795s and make sure it has the right frontface radius on it. Here's a cutaway view that shows the bearing pretty well. I labeled the bearing and outer seal diameters:

My sandblaster is currently down - stripped everything off it so I could put a real hopper on the bottom. Thread about it here:

hopper for blast cabinet

Gonna get back to blasting parts once I get that on there.