George2615

Super Member

I finally ordered and received a Thumb for using on my bucket and forks. I bought it from Greensmachine. I got the 36" model but they have shorter ones. I also bought 2 thumb base plates. One for the forks and one for the bucket.

So, here's the pics over the past couple days.

1-9 Test fitting for best location.

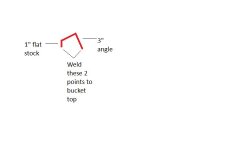

10 - I had to cut out the fork back plate for thumb base plate location. Bought a piece of 3"x3" angle 3/8" thick to mount the base on. Cut it to length and fit it in place.

11 - Drilled 5/8" mount holes in the angle.

12 - Test fit thumb plate.

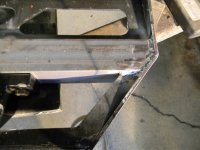

13-14 Welded in the angle to strengthen the upper section of the back plate back up.

14-18 Also added two vertical uprights where the Q.A. goes.

15-16 Welded using 1/8" 7018

19-21 Primed and painted.

22-26 Installed.

28 - Bolted the base plate on bucket after drilling the 5/8" holes. Thumb base plate bolts are 5/8" Grade 8 with nylon lock nuts.

29-32 Installed and tested.

Easy pin on set up. Just pull 3 pins, change from forks to bucket and pin back on.

Sorry but the pics are out of order. I uploaded them in order but they didn't post properly. Hovering your mouse pointer over the pic should show the pic number.

So, here's the pics over the past couple days.

1-9 Test fitting for best location.

10 - I had to cut out the fork back plate for thumb base plate location. Bought a piece of 3"x3" angle 3/8" thick to mount the base on. Cut it to length and fit it in place.

11 - Drilled 5/8" mount holes in the angle.

12 - Test fit thumb plate.

13-14 Welded in the angle to strengthen the upper section of the back plate back up.

14-18 Also added two vertical uprights where the Q.A. goes.

15-16 Welded using 1/8" 7018

19-21 Primed and painted.

22-26 Installed.

28 - Bolted the base plate on bucket after drilling the 5/8" holes. Thumb base plate bolts are 5/8" Grade 8 with nylon lock nuts.

29-32 Installed and tested.

Easy pin on set up. Just pull 3 pins, change from forks to bucket and pin back on.

Sorry but the pics are out of order. I uploaded them in order but they didn't post properly. Hovering your mouse pointer over the pic should show the pic number.

Attachments

-

$_57.JPG106.7 KB · Views: 248

$_57.JPG106.7 KB · Views: 248 -

32.JPG285.4 KB · Views: 303

32.JPG285.4 KB · Views: 303 -

31.JPG293.6 KB · Views: 278

31.JPG293.6 KB · Views: 278 -

30.JPG246 KB · Views: 363

30.JPG246 KB · Views: 363 -

29.JPG273 KB · Views: 296

29.JPG273 KB · Views: 296 -

28.JPG202.7 KB · Views: 291

28.JPG202.7 KB · Views: 291 -

27.JPG281.8 KB · Views: 274

27.JPG281.8 KB · Views: 274 -

26.JPG269.2 KB · Views: 281

26.JPG269.2 KB · Views: 281 -

25.JPG295.6 KB · Views: 501

25.JPG295.6 KB · Views: 501 -

24.JPG251.4 KB · Views: 311

24.JPG251.4 KB · Views: 311 -

23.JPG285.8 KB · Views: 349

23.JPG285.8 KB · Views: 349 -

22.JPG254.8 KB · Views: 338

22.JPG254.8 KB · Views: 338 -

21.JPG173.7 KB · Views: 276

21.JPG173.7 KB · Views: 276 -

20.JPG169.2 KB · Views: 242

20.JPG169.2 KB · Views: 242 -

19.JPG223 KB · Views: 250

19.JPG223 KB · Views: 250 -

18.JPG180.7 KB · Views: 243

18.JPG180.7 KB · Views: 243 -

17.JPG182.3 KB · Views: 261

17.JPG182.3 KB · Views: 261 -

16.JPG163.7 KB · Views: 260

16.JPG163.7 KB · Views: 260 -

15.JPG157.4 KB · Views: 225

15.JPG157.4 KB · Views: 225 -

14.JPG177.5 KB · Views: 260

14.JPG177.5 KB · Views: 260 -

13.JPG149.3 KB · Views: 233

13.JPG149.3 KB · Views: 233 -

12.JPG149.6 KB · Views: 252

12.JPG149.6 KB · Views: 252 -

11.JPG166.7 KB · Views: 236

11.JPG166.7 KB · Views: 236 -

10.JPG166.6 KB · Views: 236

10.JPG166.6 KB · Views: 236 -

9.JPG218 KB · Views: 248

9.JPG218 KB · Views: 248 -

8.JPG224.1 KB · Views: 241

8.JPG224.1 KB · Views: 241 -

7.JPG195.8 KB · Views: 244

7.JPG195.8 KB · Views: 244 -

6.JPG213.5 KB · Views: 232

6.JPG213.5 KB · Views: 232 -

5.JPG235.6 KB · Views: 297

5.JPG235.6 KB · Views: 297 -

4.JPG232.1 KB · Views: 265

4.JPG232.1 KB · Views: 265 -

3.JPG195.6 KB · Views: 286

3.JPG195.6 KB · Views: 286 -

2.JPG191.6 KB · Views: 263

2.JPG191.6 KB · Views: 263 -

1.JPG214 KB · Views: 286

1.JPG214 KB · Views: 286