Hi Tractor guys,

Now that it's spring and we're all hooking up various implements, there've been quite a few posts about how to hook up a 3-point, the value of quick hitch systems, etc.

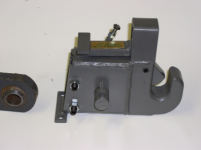

I've hooked up mowers (sickle bar and rotary), blades, etc. on my hitches over the years and now do use Pat's. It's great.

My question is, why in the world don't 3-points just come standard nowadays with some kind of built-in spring-loaded quick hitch hook system instead of the old rotating captive ball, which in fact certainly can be a pain in the neck to hook up, especially if you're all by yourself?

Must be some reason why what seems to be an obsolete system persists. What obvious thing am I missing?

Bill

Now that it's spring and we're all hooking up various implements, there've been quite a few posts about how to hook up a 3-point, the value of quick hitch systems, etc.

I've hooked up mowers (sickle bar and rotary), blades, etc. on my hitches over the years and now do use Pat's. It's great.

My question is, why in the world don't 3-points just come standard nowadays with some kind of built-in spring-loaded quick hitch hook system instead of the old rotating captive ball, which in fact certainly can be a pain in the neck to hook up, especially if you're all by yourself?

Must be some reason why what seems to be an obsolete system persists. What obvious thing am I missing?

Bill