I learned something here. But gotta ask to be sure JJ- This is true with rubber hoses right ? If it metal, There no point in having curves , am I faulty in thinking this or what ?

Here is some interesting reading. If I remember right, in aircraft hydraulic routing, you never run straight lines, because of expansion and contraction.

All hose should have room to flex, but not vibrate . You can get away with some straight lines by a short flexible ,plastic or rubber hose.

Hose routing guidelines

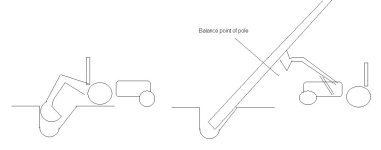

Always allow for expansion and contraction of the hose during operation by making the hose lengths slightly longer than the actual distance between the two connections. When pressurized, hose length can increase as much as 2% or decrease by as much as 4%.

If the replacement hose is too short, pressure may cause the hose to contract and be stretched, leading to reduced service life. But if a hose is too long, it can be damaged, pinched, or even severed if it gets in the way of moving machine members.

Also avoid positioning hose next to metal edges or too close to other hose. Continuous rubbing against equipment components, other hose, or objects in the operating envelope can wear away the hose cover, exposing the hose reinforcement. Once a hose's protective cover has worn away, the exposed reinforcement wires become susceptible to corrosion, wear, and, ultimately, premature failure.

Prevent abrasion by bundling together hose assemblies that flex in the same direction. Clamps, bent tube elbows, nylon ties, spring guards, and sleeves can be used to keep hose away from abrasion sources. Hose sleeves can be used to provide extra protection from abrasion. Major hose manufacturers also produce hoses with extra-tough, abrasion-resistant covers that last hundreds of times longer than standard rubber-covered hoses in hose-to-hose and hose-to-metal abrasion testing.

Use elbows and adapters to prevent inducing strain on hose assemblies and to provide neater installations that are more accessible for inspection and maintenance. Elbows and adapters also can prevent having to orient fittings in a specific position during installation.

If an angle fitting is required on both ends of a hose assembly, use it on one end only, then use a straight fitting and an angle adapter on the other. In general, it is better to use a straight adapter and bent tube fitting instead of an angled adapter and straight hose end. This promotes laminar flow, which reduces pressure drop.

And, finally, adapters should be permanently installed on tapered pipe thread ports as a way to upgrade connections to modern designs that are more reliable and leak-free.